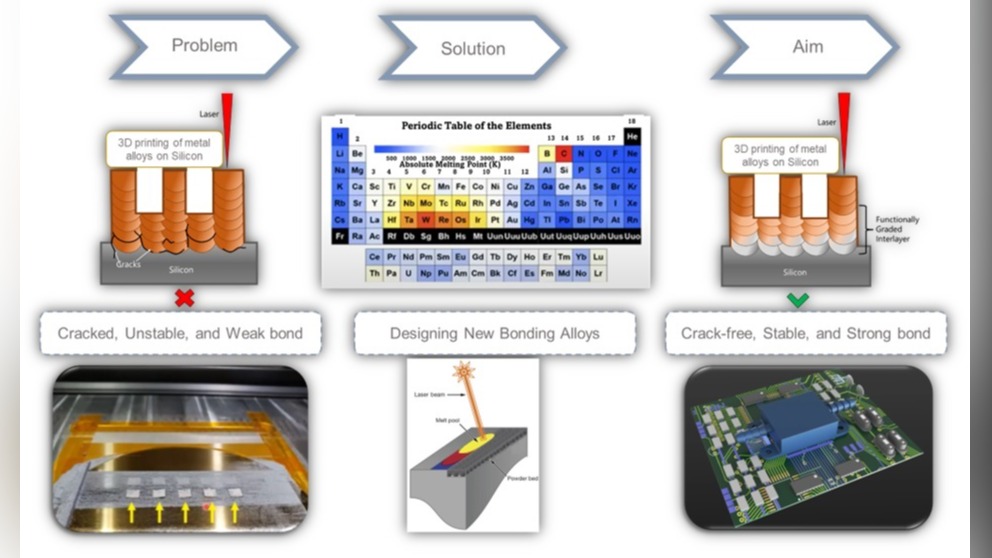

The development of high-power electronic devices requires innovative cooling systems. One promising approach is laser powder bed fusion (LPBF). While LPBF has been used for metallic cooling systems (e.g. microchannel heat sinks), a remaining challenge is the direct integration of these structures onto silicon-based electronic devices. Limited efforts have been made to establish a mechanically robust connection between metals and silicon due to thermal and compositional incompatibility. To address this issue, we employ LPBF to develop an interlayer between a metal heat sink (copper or aluminium) and silicon, enhancing metallurgical bonding and reducing thermal stresses. This goal is pursued through three objectives:

Objective 1

To select interlayer materials for crack-free, strong metal/silicon bonds: interlayer alloys are chosen through literature review and computational simulations based on two requirements: (i) avoiding the formation of brittle intermetallic compounds and (ii) good thermal compatibility of the interlayer with both silicon and heat sink, mitigating thermal stresses and cracking.

Objective 2

To optimize LPBF process: LPBF parameters are optimized and post-processing heat treatments are conducted to ensure strong Si/interlayer/metal bonding and minimize thermal stresses and defects.

Objective 3

To establish composition-property-performance relationships: materials analyses are performed for deep understanding of the microstructural evolution across silicon/interlayer/metal during LPBF, and phase transformations/homogenisation after heat treatments. Physical properties (e.g. thermal conductivity), and thermal/mechanical performance of the interface will also be assessed

The novel interlayer alloys and approaches developed in this proposal will enable the production of the first-ever metal microchannel heat sinks on silicon substrate by LPBF, a breakthrough in the electronic package without using thermal interface materials for space cooling applications.