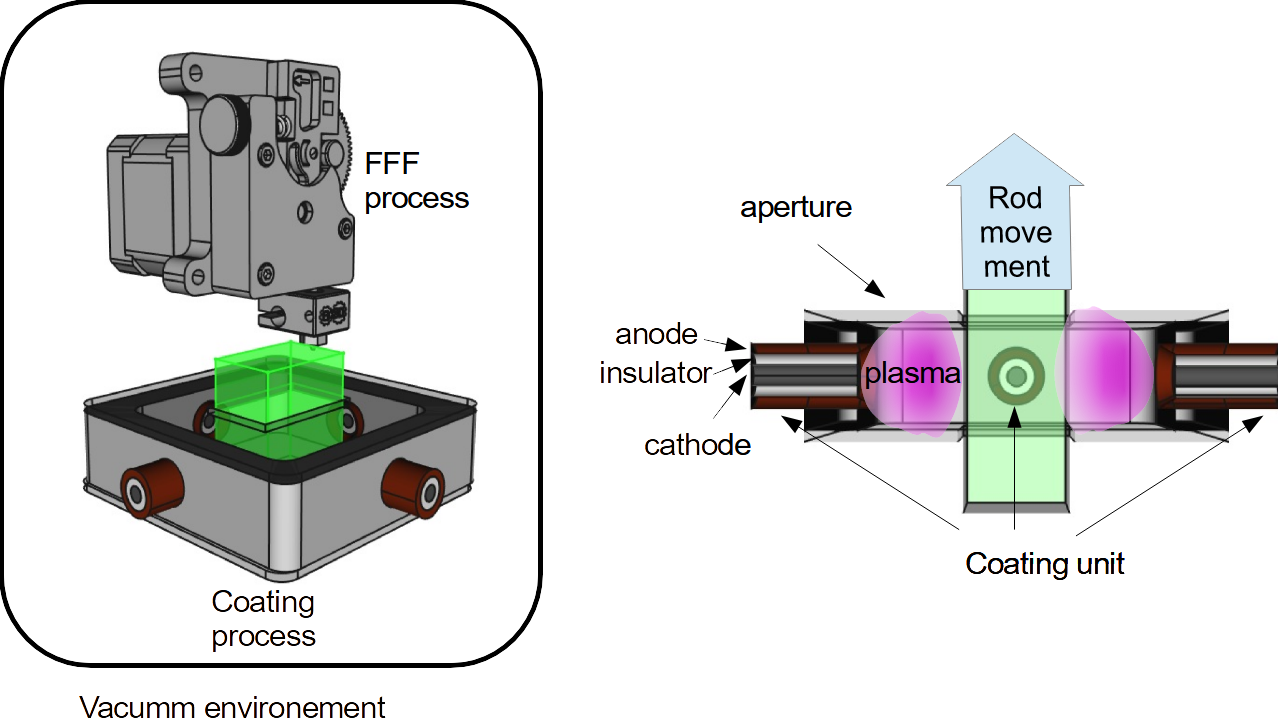

Today techniques for on-orbit manufacturing in reduced atmosphere are needed for building large structures such as antennas, solar panels and radiators. It was already demonstrated that FFF based additive manufacturing is suitable for zero gravity environment and can produce structures larger than the printer itself. PEEK is an especially interesting polymer for space applications due to its high stiffness and low thermal expansion, as well as higher resistance to beta and gamma radiation. However PEEK and other polymers have a poor resistance to UV and atomic Oxygen, which are considered one of the main reasons for the degradation of surfaces exposed to the Space Environment [1] [2]. We suggest to operate the FFF process in vacuum and to enhance it with a post-processing coating step in order to extend the lifetime of polymer based structures in space. Therefore we propose to use a compact, lightweight (total weight ~250 g) and low power (starting from 1 W) coating system based on vacuum arcs, which can coat the outer surface of long 3D printed structures. It is able to produce thin metal [3] and metal oxide coatings from sintered cathode materials [4]. Compared to other methods like Atomic Layer Deposition [5], vacuum arcs do not require gas or liquid precursors. They can be operated in deep space since no ambient gas pressure is required. Moreover vacuum arcs have already been operated in space environment as electric propulsion system for Cubesats [6]. In our activity we will use a previously developed FFF printer, operating in high vacuum to demonstrate that it is possible to manufacture and coat a model part, without breaking the vacuum. Therefore we will adapt the overall design to be able to coat the outer surface of the model part after printing. We will first print and then coat a model part with Al coating for UV protection and investigate the UV reflectivity and mechanical properties of the printed coating ( corresponding to TRL 4).