Duration: 14 months

With reduced costs to access orbit, the ability to perform value-adding operations after launch, better known as In-space Servicing, Assembly & Manufacturing (ISAM), is becoming a key strategic interest for space industry competitiveness, defence, and space exploration. On-orbit manufacturing and assembly processes have been studied from a system level (ESA - OMAR, EU - PERIOD…) and even demonstrated in some cases (ESA - metal 3D printer). While these activities show the relevance of Out-of-Earth manufacturing, especially for high-durability metal materials processing, they lack technological solutions for space-compatible process monitoring & Quality Control methodologies, which are critical to the automation and industrial adoption of these advanced manufacturing methods.

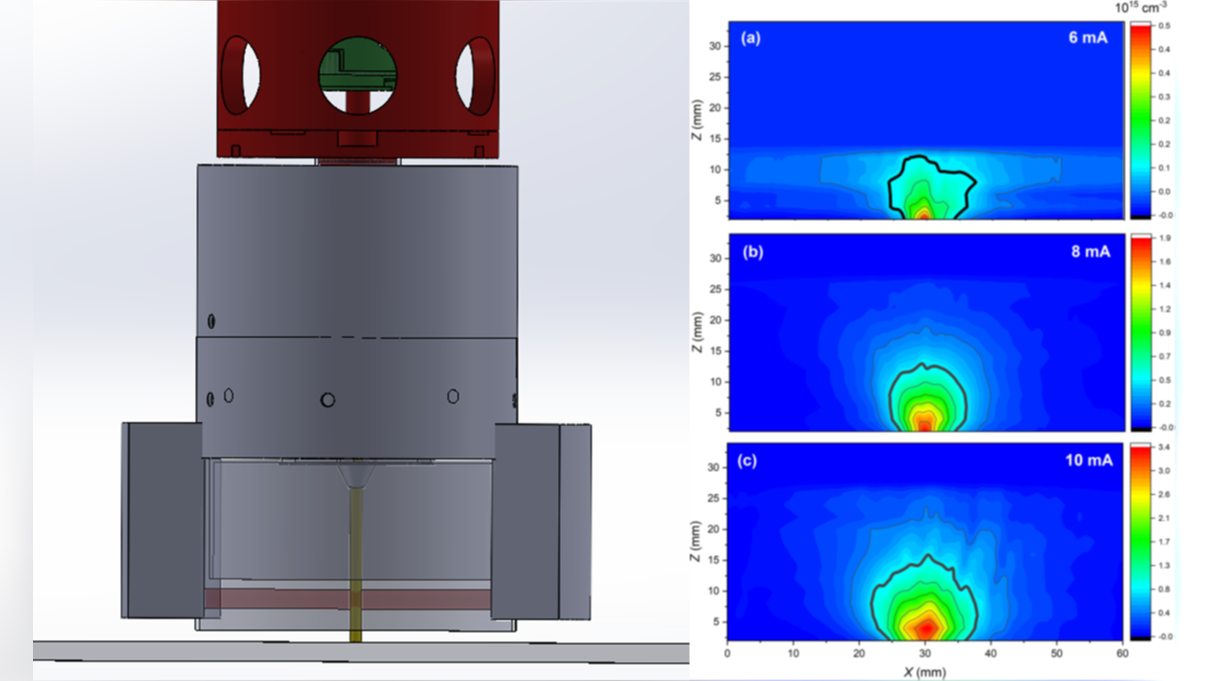

The proposed Early Technology Development aims to address this by transforming the metal vapor generated during processing in space into a Key Process Indicator (KPI) for Quality Assurance and contamination monitoring. This unconventional approach bypasses the limitations of optical or line-of-sight monitoring systems and unlocks a lightweight, long-lifetime quality control solution. A novel metal vapor propagation simulation will be developed in parallel with an innovative, robust, and cost-effective in-situ measurement technique, and its performance will be characterized experimentally using high-vacuum open-space welding. Testing will be performed on an existing high-vacuum electron-beam welding testbed and will include in-situ vapor measurements. The results of this activity are also designed to be relevant to other in-space material processes such as metal 3D printing and homogeneous welding. Target applications include short-term market adoption opportunities, e.g., on-orbit capture, end-of-life management, and defence use-cases, but also long-term disruptive solutions ranging from on-orbit assembly of large-scale infrastructure to in-situ spare parts manufacturing for exploration missions.