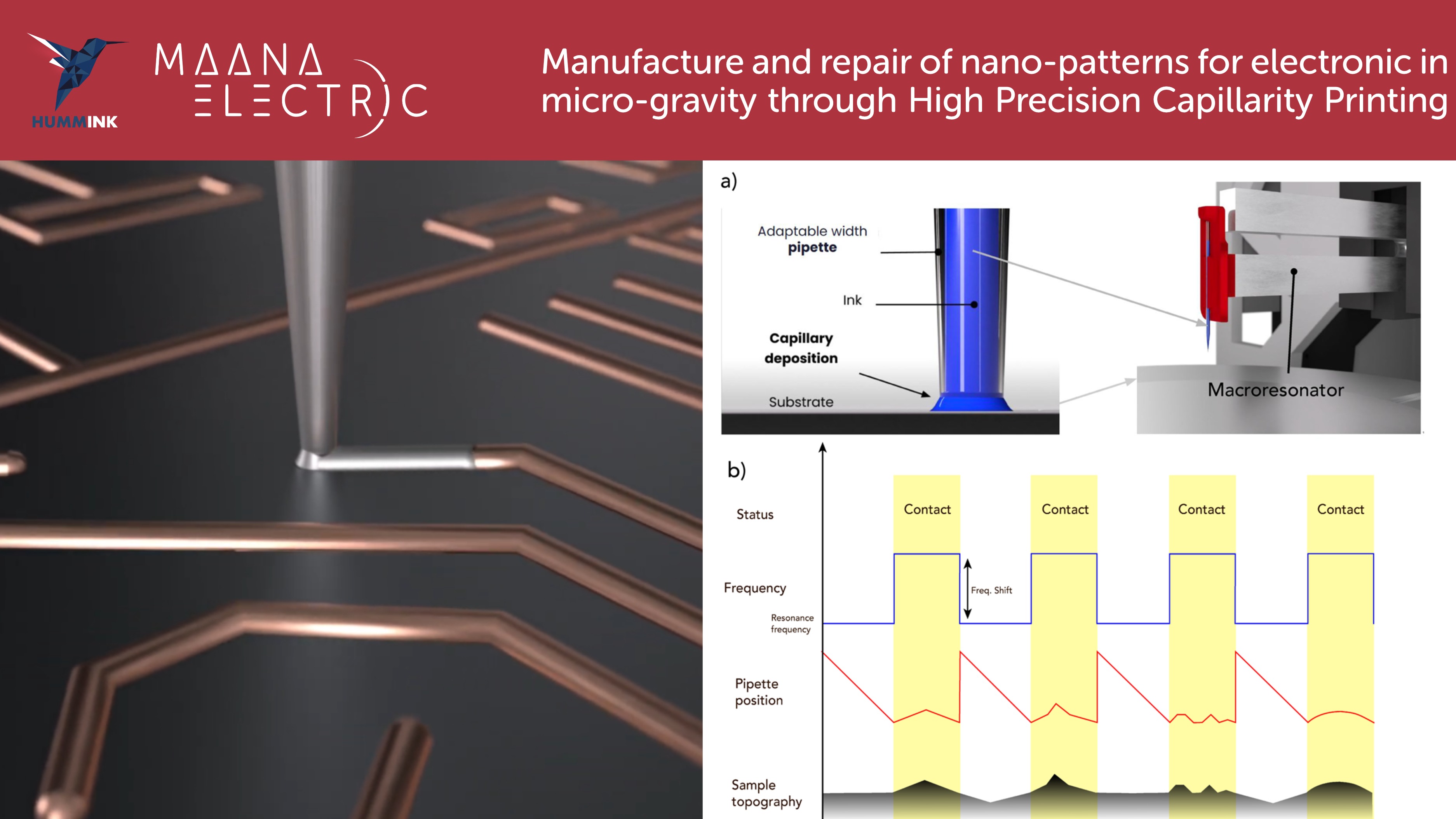

High Precision Capillarity Printing (HPCAP) is a patented technology developed by Hummink to deposit any material on any substrate with resolution from 50 µm down to 100 nm [1]. It is directly derived from AFM (Atomic Force Microscope) technologies, replacing scanning probes with nano capillaries. These “nanopens” are filled up with a liquid ink, reaching viscosities up to 100,000 cP. They are attached to a macro-resonator which oscillates at a controlled frequency. When the substrate approaches the tip of the oscillating nanopen, a first drop of liquid is pulled out thanks to capillarity. The formed meniscus is detected by a slight frequency shift of the resonator. The printer is able to stabilise the meniscus and move the nanopen in xyz direction to print the desired pattern. When compared to typical inkjet printing, the capillarity deposition is not affected by gravity. Moreover, surface tension retains the printed pattern regardless of their orientation. These features make HPCAP the perfect candidate for printing in microgravity conditions. Several different materials can be printed while in solution in the ink, such as silver and gold, which makes the technology suitable for printing or even repairing nano/micro-electronics components or PV cells. This capability would allow in-orbit manufacturing of such components, with an advantage with respect to logistic and reliability of resupply from Earth. While the core technology is already developed for terrestrial applications, several modifications on both process and hardware level are required to develop a unit for use in space. This idea proposes the development of a prototype of HPCAP able to work in microgravity. The consortium formed by Maana Electric and Hummink puts together complementary expertise in fields of space engineering, ISRU concepts and knowledge of HPCAP.