Duration: 12 months

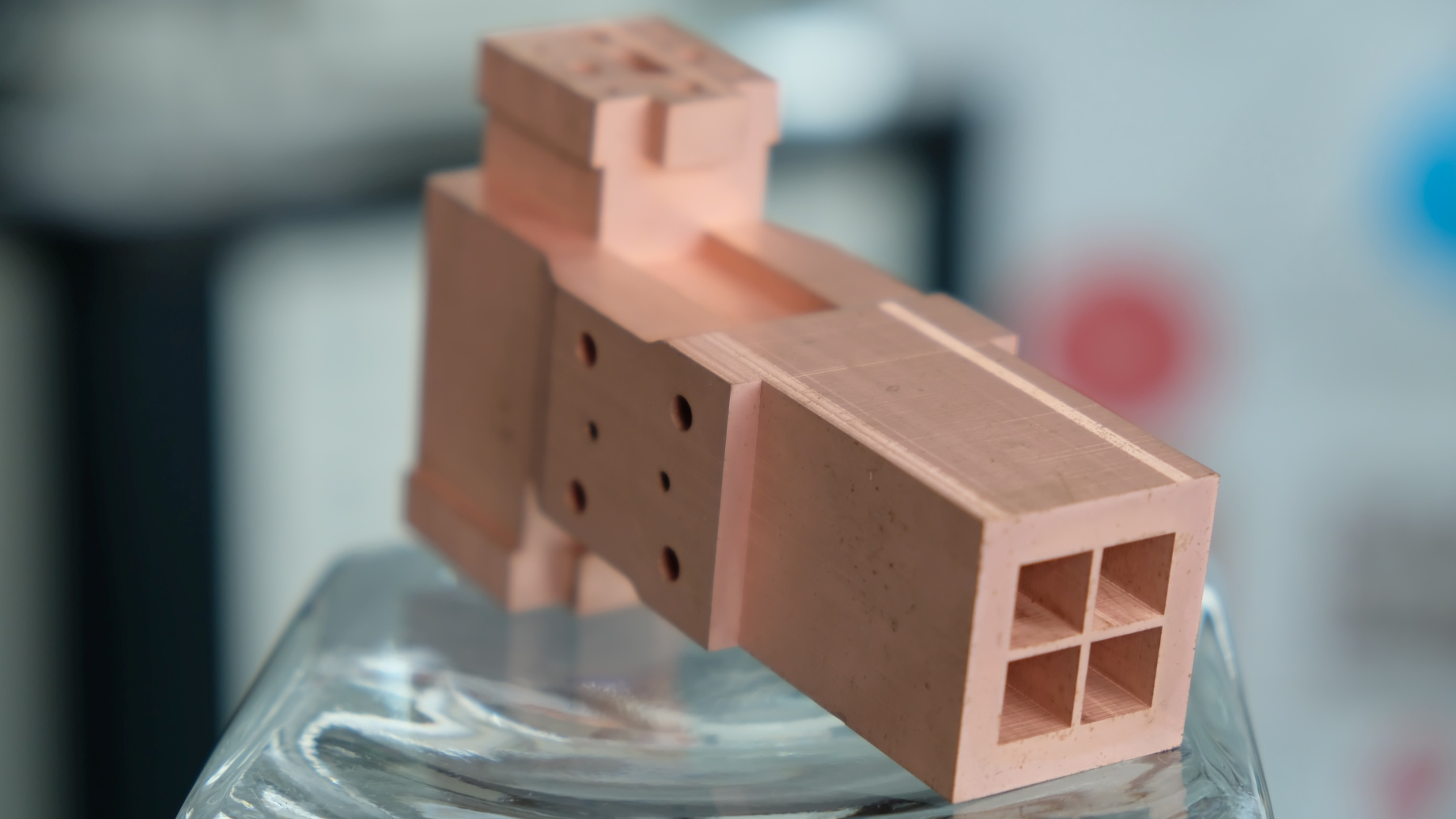

The objective of the study is the development of a strategy for the functionalization of 3D-printed polymeric satellite antennas through surface metallization techniques. 3D-printing (3DP) is key to the next generation of space antennas, because it enables the design in a reduced number of pieces, with significantly increased accuracy values for applications at higher frequencies (Ka-Band and Q/V-Band), a perfect alignment between pieces, and very low surface roughness for high levels of cross-polarization discriminations. Additionally, using a polymer as material results in lightweight, payload-reducing parts with mass savings of up to 90 % which are directly related to cost savings, and the much faster production of complex parts compared with traditional manufacturing. The basis for the proposed study is a light curable resin based on bismaleimides. This high-performance polymer class is known to the aerospace industry for pre-pregs and adhesives and thus has the potential to reduce the initial hurdle of industrial acceptance. 3D-printed specimens from this base material already passed the thermal vacuum outgassing test according to ECSS_Q_ST-70-02C. The subsequent metallization of the polymer surface is necessary as the used polymers work as insulators. Novel composite concepts are planned to address adherence between polymeric substrate and metal layer via interlocking improvement and thermal expansion mismatch compensation. These demanding tasks can be achieved by the Hot Lithography process established by the company Cubicure GmbH and a subsequent coating procedure that provides functionality via good adherence and uniform plating of finally metalized 3D surfaces. Therefore, the proposed concept is the tailoring of 3DP material to the metallization process, while maintaining the necessary material properties for the space environment and the design concept for the 3D production of high-frequency antennas.