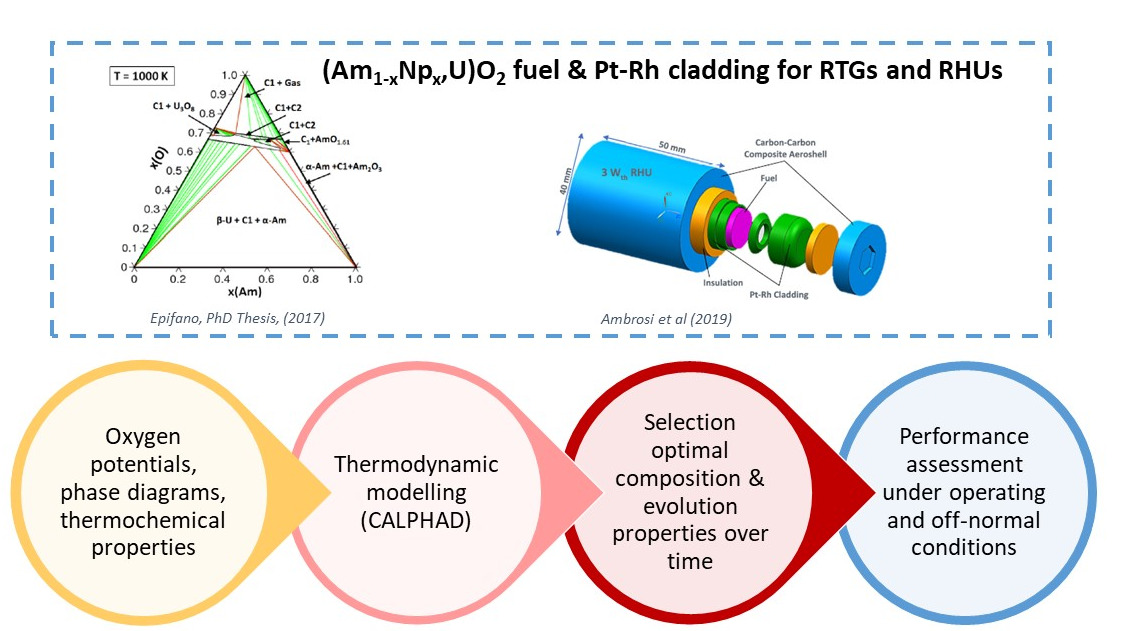

241Am is currently the preferred choice for the fuel of RTGs and RHUs in Europe, as it can be produced at an acceptable cost, and the extraction and purification technologies for its production are already mature. Ceramics including AmO2 and Am2O3 have been envisaged for the fuel form. However, because the final oxygen-to-metal ratio of the americium oxide is challenging to control under sintering and operating conditions, uranium-stabilised americium oxide (Am,U)O2 has been investigated in recent years as a more promising solution. During operation, thermal and mechanical stability of the fuel material and Pt-Rh cladding must also be ensured, with minimal interaction between the two. To this date, the (Am0.8U0.12Np0.06Pu0.02)O1.8 fuel, synthesized and characterized at the JRC by “trial and error”, has shown good performance under sintering and irradiation. In this project, we propose to follow a more systematic thermodynamic approach to gain (i) a thorough understanding of the thermodynamics and phase equilibria in the Am-U-O system in regions of relevance for RTGs and RHUs development, combining experimental investigations with a thermodynamic modelling approach; (ii) predict the performance of the (Am,U)O2-x fuel over a wide range of compositions in representative temperature and oxygen potential conditions; (iii) predict the change in properties and performance of the fuel over time as the 237Np content will build up following alpha decay of 241Am; (iv) gain insight into the chemical interaction between (Am,U,Np)O2 fuel and Pt-Rh. A modelling tool will be delivered at the end of the project, that will allow to select an optimal fuel composition, and to simulate its properties in any set of conditions (i.e. normal and off-normal) and over time. Such a tool will support and complement the fuel optimization done to this date by JRC and the University of Leicester, and the necessary safety demonstration of the Am sealed source in front of regulatory bodies.