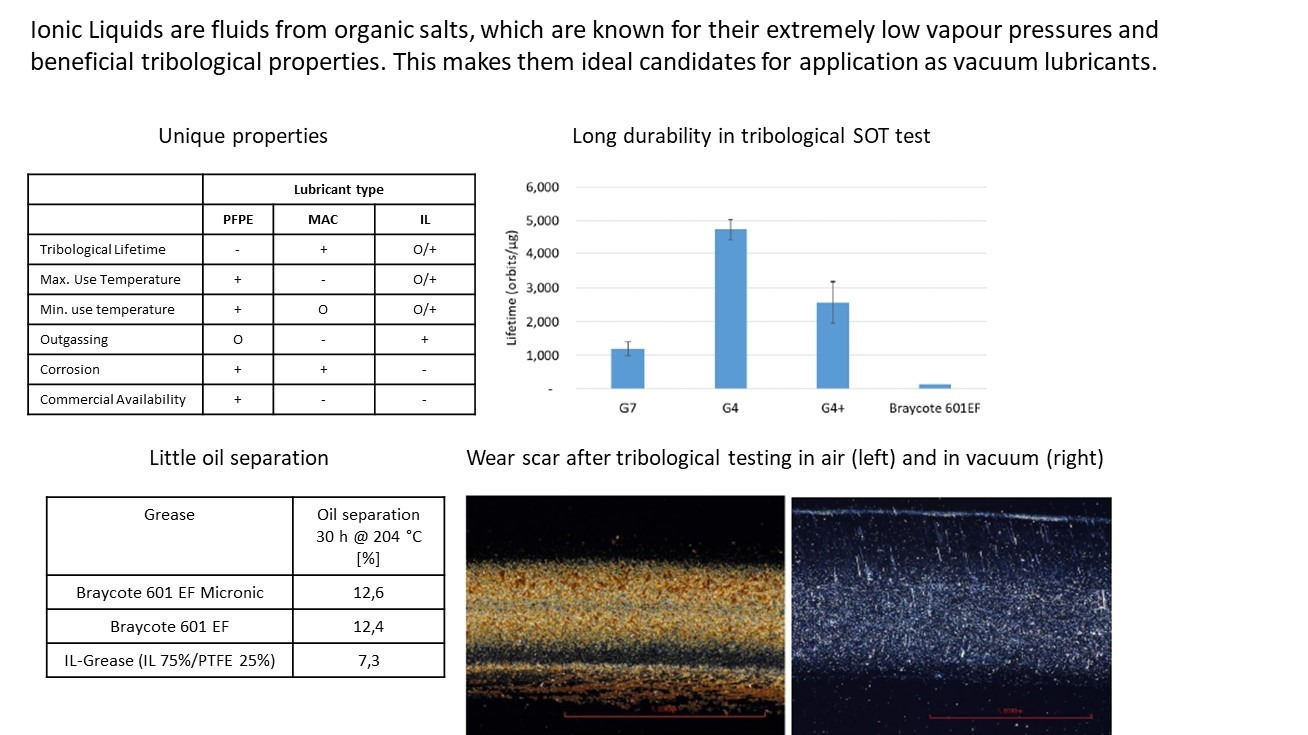

Ionic Liquids (ILs) are fluids from organic salts that are known for their extremely low vapour pressure, and a high resistance against temperature and thermo-oxidation. Various publications have outlined their outstanding tribological properties. This enables ILs as ideal candidates for highly durable and low-outgassing lubricant formulations, and could already be demonstrated by outgassing testing of an oil formulation according to ECSS-Q-ST-70-02C. In another experiment, a sample IL remained fully stable after 16 weeks of storage at 200 °C under thermooxidative conditions. Further previous work at MATERIALES has shown that basic and preliminary IL grease formulations display significantly longer lifetimes (factor x10-50) in tribological spiral orbital testing (SOT) compared to fully formulated perfluoropolyether (PFPE) based greases, such as Braycote 601 EF, that are very widely used in space applications. Oil separation testing (according to ASTM D 6184; 204 °C/30 hours) revealed that the IL greases showed a 40-50% lower oil loss in comparison to fully formulated PFPE greases. The main area of concern with regard to ILs is a corrosive impact on metallic materials. While methods to mitigate corrosion under static conditions have been developed, corrosion can still occur in dynamic/tribological test situations. Current work at MATERIALES addresses this topic by investigating different formulations that make use of ILs or inorganic components with a protective effect. The use of inorganic additives is advantageous due to their low outgassing risk, and the ionic nature of ILs has shown a high compatibility. Once, the corrosive effects are controlled, ILs would become a highly attractive alternative to current commercially available products on PFPE or MAC (multiple alkylated cyclopentane)