With rapid advances in space technologies, the power and energy demands have increased dramatically, motivating the need for efficient and compact energy conversion and storage systems, e.g. regenerative fuel cells (RFCs). The fundamental challenge is to precisely engineer materials 3D structure and surface composition to enable ultra-high performance (high power) and extended durability through tailored material interfaces. Thus, high-resolution 3D printing emerges as a promising route.

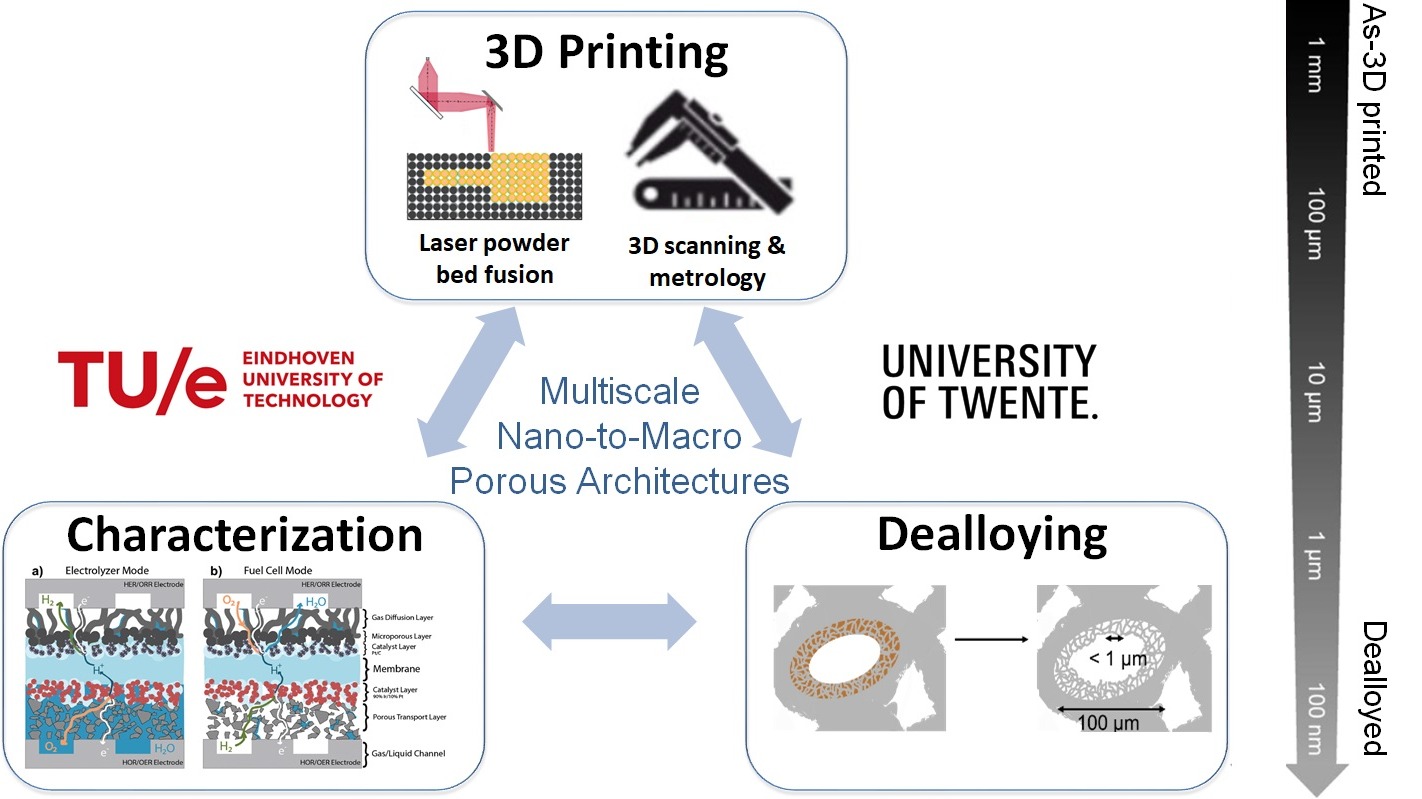

In this project, we will develop 3D printed metallic hierarchical nano-porous structures with engineered macro-architectures by combining 3D printing (laser powder bed fusion) and electrochemical dealloying.

First, the computer-designed macro-porous network structure with 20-100 μm features will be 3D printed. Then, it will be coated with electrochemical methods (electrodeposition and dealloying) to prepare nanoscale pore morphology (50 to 500 nm). Finally, the hierarchically-organized structures will be implemented in RFCs as porous transport layers and catalytic layers and characterized in terms of round-trip efficiency and overpotentials in-situ.

3D hierarchical porous metals, derived from integrated 3D printing and dealloying, have a unique bi/tri-modal solid/void structure that provides a large surface area, facilitates mass transport, conducts electrons and heat, and cushions mechanical compression, making them ideal candidates for various energy applications.

Expected impact

- Development of innovative digital materials for advancing the state-of-the-art in reversible electrochemical energy storage.

- Improvement of round-trip efficient and durability of RFCs by decreasing mass transfer and kinetic over-potentials and using new reactor concepts.

- Innovative process technologies related to 3D printing, interface optimization, coating development and surface modification.

- Advances in future system architecture thanks to digital manufacturing.