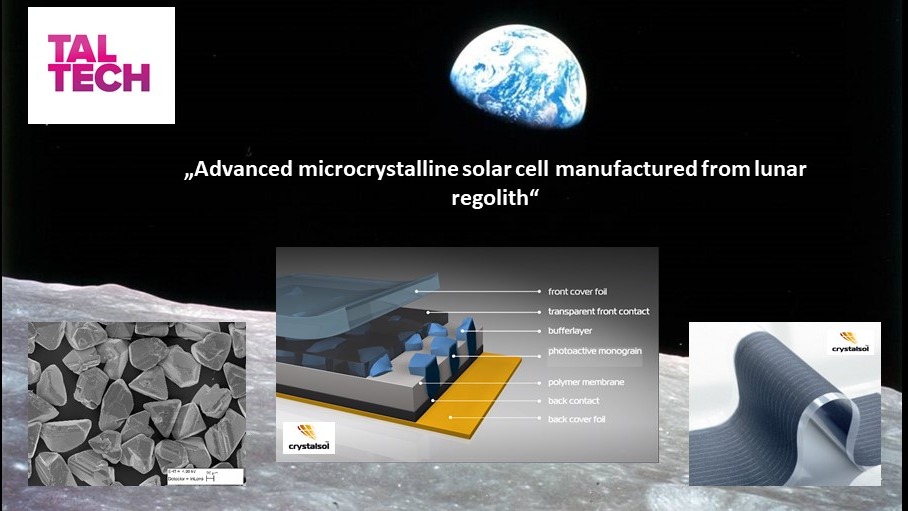

One of the most important issues in establishing a lunar outpost will be the availability of energy sources. Solar panels is one of the most promising options due to the fact that on Lunar South pole, that is selected as a future lunar outpost location, some areas are constantly illuminated by sunlight. This would enable constant electricity production from sunlight without the need of massive temporary storage such as batteries or inertia wheels. Instead of bringing the solar panels from Earth, it would be more perspective to find a way to produce them in situ on the Moon from the resources available in lunar regolith. Main objective of this study is to find the suitable semiconductor (elemental, binary or multinary compound) available in lunar regolith that can be synthesized in microcristalline form and can be used in monograin layer (MGL) solar cell. The MGL solar cell concept for semiconductor compounds was proposed more than 50 years ago by researchers of the Philips Company, additional developments, modifications and patents were taken by the TalTech researchers and crystalsol GmbH. The MGL solar cell has a superstrate solar cell structure: graphite/absorber/buffer/conductive oxide layer/substrate (glass or polymer film), where the absorber is a monolayer of nearly unisize, with a typical diameter of 40 μm, semiconductor powder crystals embedded into a layer of epoxy without contaminating the upper surfaces. It is the completely different from traditional crystalline - or thin film solar cell technology, where lightweight solar panel technology combines the advantages of potentially high efficiency mono-crystalline material and low cost roll-to-roll panel production, enabling to manufacture flexible, lightweight and cost-efficient solar panels that very likely allow us to cover vast areas with minimum cost.