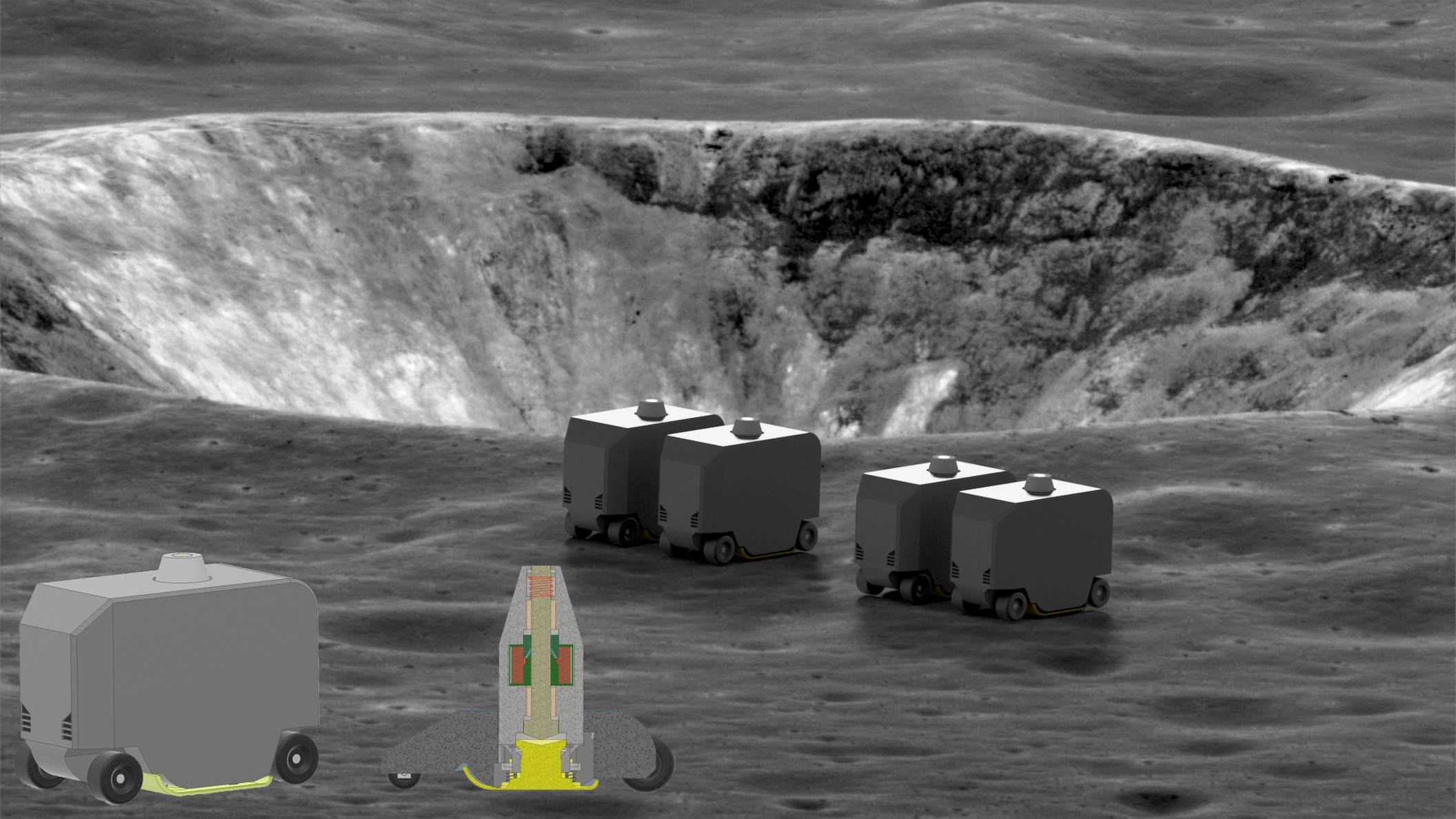

By leveraging terrestrial best practices in construction industry and adapting them to planetary mission constraints we can develop technologies for large-scale construction projects on the Moon. One of the immediate needs for a successful Moon base project is construction of landing pads, berms and roads, which would enable access to Regions of Interest for more complex space resources activities. Early-stage development in that area should focus on "dirt-simple" technologies. Currently, such operations are envisaged with the use of heavy terrestrial-like equipment. To reduce mass and energy requirements, we propose that large-scale construction projects could utilize percussion-based plate compaction techniques. Percussion has proven flight solutions that enable significant enhancement of space mission capabilities. It relies on accumulation of potential energy and its subsequent impulsive release. A robotic system of multiple lightweight compactors or single large compactor could be used to compact near-surface regolith, densify it to increase its bearability and even level it - enabling traversable roads, landing-launch pads or even hardened groundworks of habitats without the use of binders. Large-scale construction efficiency by utilization of low frequency - high impact energy percussion or high frequency - low impact energy percussion should be investigated. Regolith compaction could be conducted in two modes: mechanical-only, where only hammering action is employed, or in a hybrid mode, where hammering action is preceded with microwave or solar sintering of regolith. Sintering and compaction of regolith could also provide dust mitigation, which is crucial for landing pads design, but also could be applicable for space-sourced photovoltaics development or seismic measurements. Investigation of this concept and its scalability would bring us closer to the idea of a sustainable Moon Village.