Duration: 12 months

As ESA advances launcher reusability and sustainable space operations, ensuring structural integrity of launcher components exposed to complex forces and extreme conditions during operation becomes critical. Residual stresses accumulate during manufacturing and operation of any metal component and can critically affect the component's strength, safety, and service life. However, current non-destructive bulk residual stress measurement techniques require transporting components to specialized facilities, and even then, most large-scale components cannot be measured effectively.

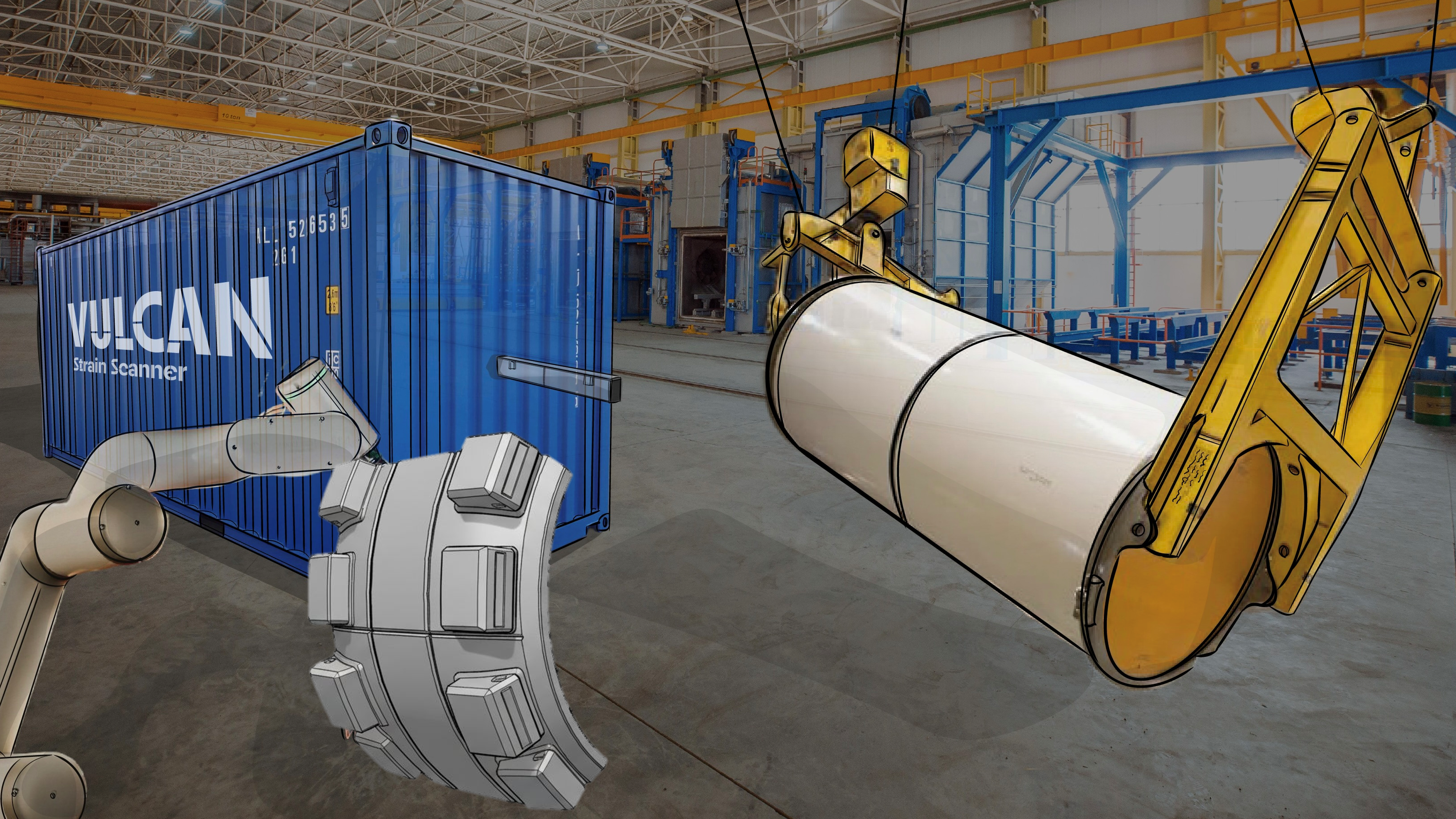

This project will design a tailored ultra-compact strain scanner for accessible and efficient on-site, non-destructive, bulk residual stress measurement on large metal objects, such as launcher parts. Our approach leverages recent advances in compact neutron sources and tailored detection systems to bring this powerful analytical capability from specialized research facilities directly into industrial environments.

Building upon DTI's and DAES’s existing expertise from the Eurostars VULCAN project—which delivered the design and digital twin for an ultra-compact neutron strain scanner capable of measuring RS in small and mid-sized objects—this activity will adapt the design and explore advanced hardware solutions capable of handling large objects, including recycled launcher structures targeted for reuse.

Combined with recent developments within standardisation and harmonisation of data acquisition and evaluation procedures, such as those developed in the Horizon 2020 EASI-STRESS project, this approach ensures reliable, repeatable, and efficient measurements compatible with aerospace QC systems. This integration of residual stress measurements into industrial QC enables cost-efficient and safe reuse of launcher components while supporting ESA’s goals for sustainable, economically competitive European space access.