Duration: 18 months

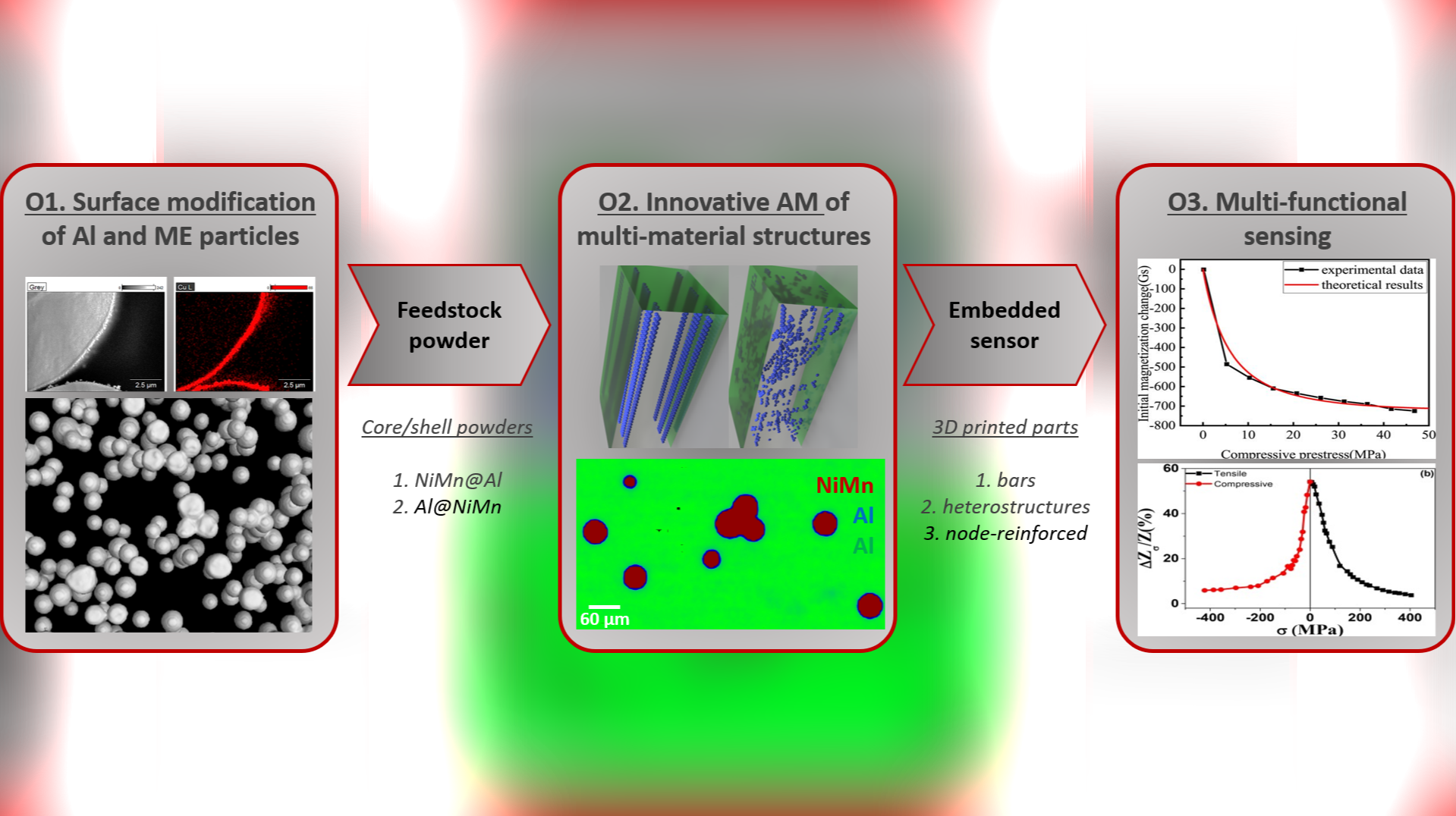

WISH introduces a novel wireless structural health monitoring (SHM) approach for space, focusing on real-time, in-situ stress monitoring in aluminum structures. Still in early development, this research promises to revolutionize material integrity in space, offering a more reliable/efficient SHM approach. Aluminum alloys with a yield strength of 200-600 MPa, suffer irreversible plastic deformations beyond this range, marking the end of their lifecycle. Methods for measuring internal stress in metals usually provide localized data. Strain gauges record stress at the surface contact, while embedded optical fibers detect deformations from the alloy's internal surface. These techniques limit overall internal stress monitoring in the structure and require electrical or optical connections. WISH leverages magnetoelastic (ME) materials, such as NiMn-based magnetic shape memory alloys (MSMA), integrated with additive manufacturing (AM) techniques and it has three main Objectives. Obj1: Development of new feedstock powders that show proper AM processability and provide new functionalities to the printed parts. Surface modification of ME powder will also be considered to avoid interaction between molten Al and ME particles during printing. Obj2: The use of ME particles in AM to enable the selective placement of active materials and monitoring of critical areas, enabling the manufacturing of structural parts with wireless sensor capabilities while producing complex, lighter structures that improve performance and reduce material use. Obj3: Implementation of MSMAS alloys to monitor internal stresses in aluminum structures, exhibiting changes in magnetic properties under mechanical deformation, providing in-situ, wireless, and real-time stress data. NiMn-based MSMA will be used to ensure accurate sensing over a broad stress range (100-700MPa).