Duration: 18 months

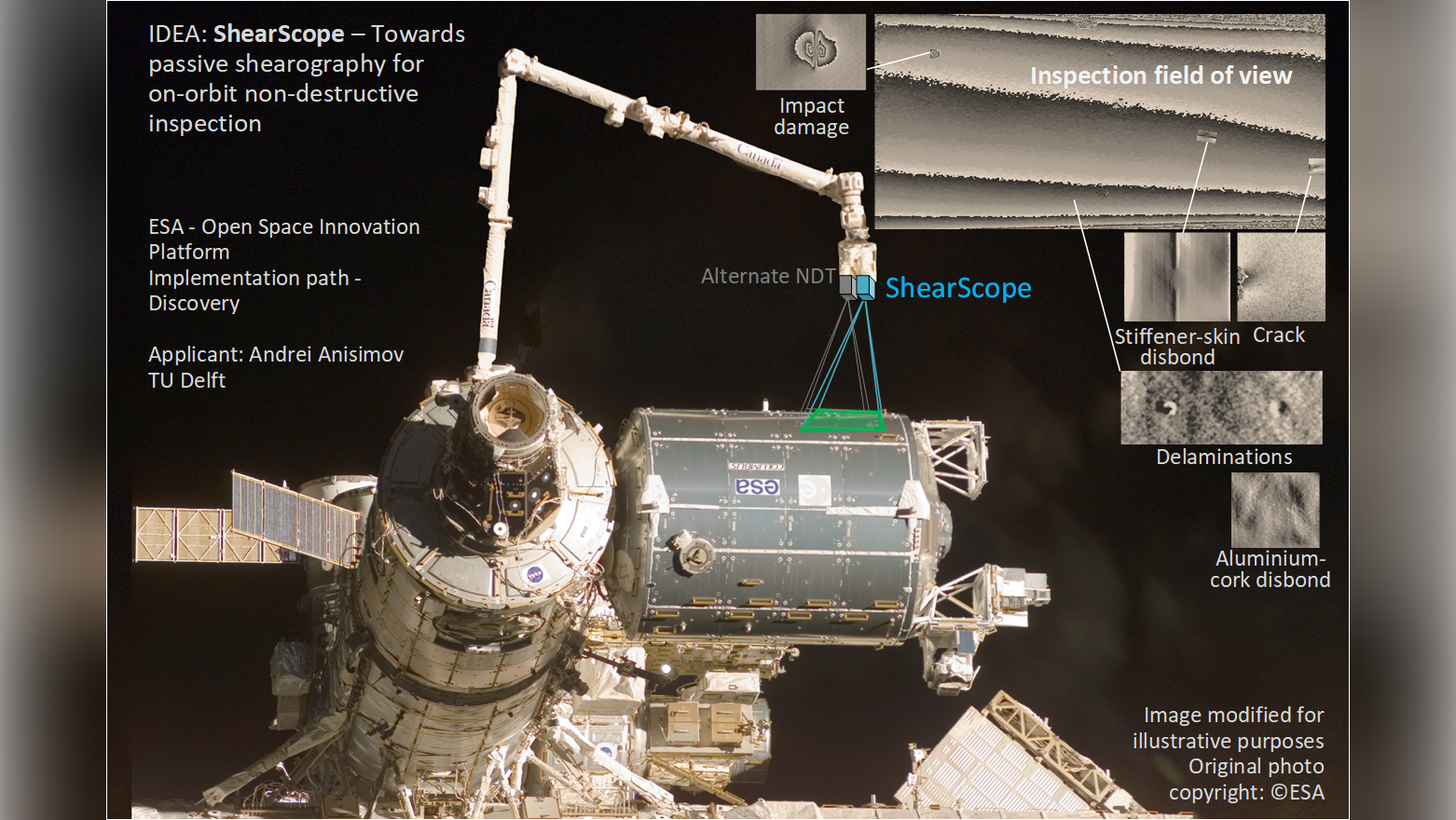

Current on-orbit inspections of space structures rely mainly on visual or video checks, which reveal only major visible issues. As spacecraft structures become larger and more complex, risks from micrometeoroids, orbital debris, and joint failures increase, while subtle defects such as cracks or disbonds often remain undetected. Following the Columbia incident, non-destructive testing (NDT) gained renewed importance. Although space structures are routinely inspected on the ground, on-orbit NDT capabilities still lag behind.

Among the various NDT techniques, shearography—a full-field speckle pattern shearing interferometry—stands out for its non-contact and highly productive inspection performance. It detects microstrain-level surface irregularities induced by external excitations such as heat or vibration, captured by cameras under laser illumination. This high strain sensitivity enables the identification of small yet critical defects, including closed cracks and kissing bonds.

In ShearScope, we aim to explore the feasibility of passive shearography inspection and develop a concept prototype for ground laboratory tests. The goal is to eliminate power-demanding excitations by leveraging natural sources, such as orbital sunrises or internal pressure variations. This approach represents the first step toward a future autonomous shearography instrument capable of inspecting space structures in orbit, potentially integrated into robotic manipulators alongside complementary NDT methods like thermography.

The strength of shearography lies in its mechanically interpretable results, which can support predictive assessments such as residual life estimation. At TU Delft, recent advances have extended shearography’s application to detecting sub-millimetre and deep defects and inspecting curved geometries—capabilities often beyond commercial instruments. ShearScope aims to build on these advances, contributing to more reliable, energy-efficient, and autonomous on-orbit inspection of space structures.