This project proposes to develop and test the utilization of locally available resources during lunar exploration, particularly focusing on lunar regolith and Limnospira (Spirulina) as potential materials for In-situ Resource Utilisation (ISRU). Lunar regolith offers various uses, including fuels, oxygen, water, shielding, and construction material for additive manufacturing. Meanwhile, Spirulina is a potentially available local material provided via the MELiSSA project, a European community's spaceborne circular life support system. Spirulina's potential uses encompass food production, water and oxygen recycling.

In this project, it is proposed to go beyond its primary purpose of CO2 and nitrate recycling as well as food utilization: It will also be used as additive into parts manufacturing via Fused Granular Fabrication (FGF-) 3d printing. Blue Horizon (BHO) has explored the use of Spirulina as a primary component in 3D printing [1]. While these materials hold promise, further research and optimization are needed to enhance their potential applications in lunar exploration and life support systems.

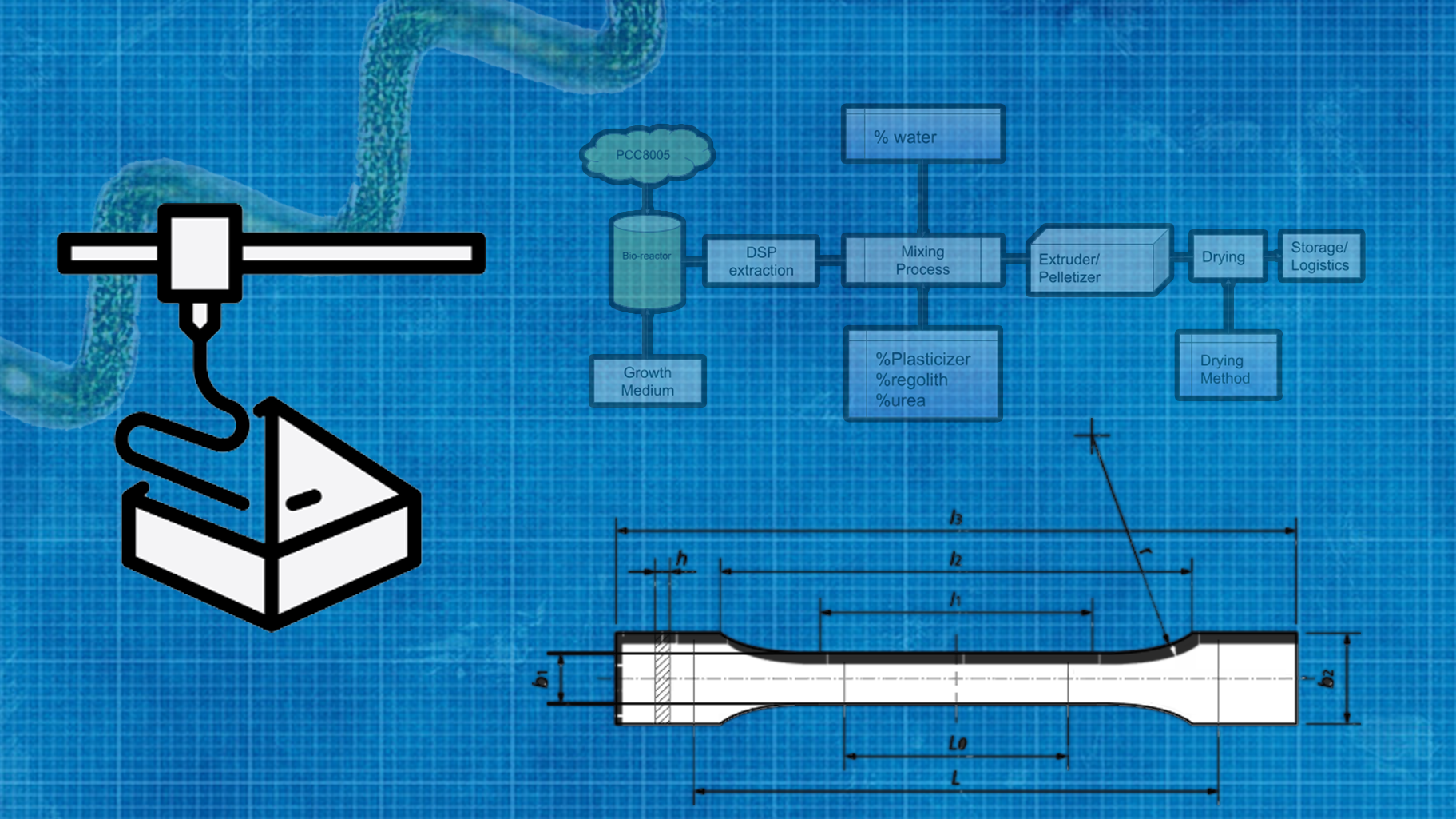

While 3D printing technologies with regolith have been extensively studied, the main novelty comes from the combination of different raw materials including plasticizers, urea (from the crew's urine), regolith simulant and Limnospira PCC 8005 biomass as it is obtained from MELiSSA C4a compartment. Therefore, large parts of raw materials are potentially available in-situ within a future lunar base/settlement. A DoE study shall be created, based on the compositions of the beforementioned 3-4 raw materials. The various blends shall be mixed, dried, made into plastic-like pellets and fed into a commercial 3D FGF printer. Mechanical properties shall be investigated by standard mechanical tensile testing (e.g. ASTM) of printed test specimens to suggest most promising formulations of the new blended material.

Specifically, in this activity we will

- Find an optimal combination of material(s)/additive(s) to produce solid spirulina pellets with material properties suitable for FGF 3D printer, with the partial limitation of raw materials. Among the raw materials are 1) biomass obtained from Limnospira indica (PCC8005) cultivations which mimic the bioreactor of MELiSSA C4a compartment, 2) plasticizers including urea and 3) filler specific to the space domain, in this case a regolith simulant.

- Process the formulations including harvesting of biomass, compounding and pelletization.

- Test 3D printability of the compounds

- Print test specimens for mechanical testing and perform standardized mechanical testing

[ref0]Solar 3D printing of lunar regolith - ScienceDirect

[ref1]https://www.melissafoundation.org/download/889

[ref2] https://doi.org/10.7480/spool.2021.2.5268

[ref3] https://nebula.esa.int/content/conceiving-lunar-base-using-3d-printing-technologies

[ref4] https://www.artme-3d.de/extruder-mk1-en/

[ref5]https://felfil.com/