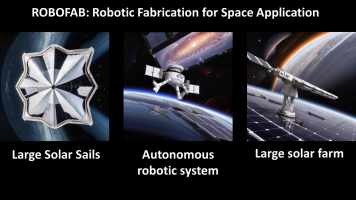

The project addresses a critical challenge that the space industry is facing: the limited capacity for giant-scale structure fabrication in space due to constraints in launch-volumes and launch costs. Current space missions are hindered by the inability to construct expansive structures in orbit such as giant solar sails, giant solar farms and giant mirrors for telescopic applications or as concave mirrors for focusing light.

ROBOFAB aims to enable space manufacturing by leveraging robotic fabrication technologies to overcome the limitations of traditional assembly methods. As a leading supplier of robotic systems for space applications, our project focuses on the development of advanced robotic arms capable of intricate fabrication tasks in the space environment paired together with the possibility of carbon tube manufacturing and 3D-printing in space. At the heart of ROBOFAB is the concept of a single satellite equipped with rolled up carbon tube to form large structures and 3D printing capabilities for e.g. intermediate pieces. By consolidating these capabilities into a single platform, ROBOFAB enables the on-demand fabrication of large-scale structures directly in space. This breakthrough approach eliminates the need for costly and logistically challenging launches of pre-fabricated, or complex folded components, paving the way for unprecedented advancements in space manufacturing.

The integration of robotic fabrication technologies into a compact and versatile satellite platform represents a shift in space manufacturing. With ROBOFAB, we envision a future where the construction of space infrastructure occurs on-site in orbit, unlocking new possibilities for space exploration and utilization, thus allowing the possibility to create large base structures for commercial space stations or even pathing the way for a rotating wheel space station.