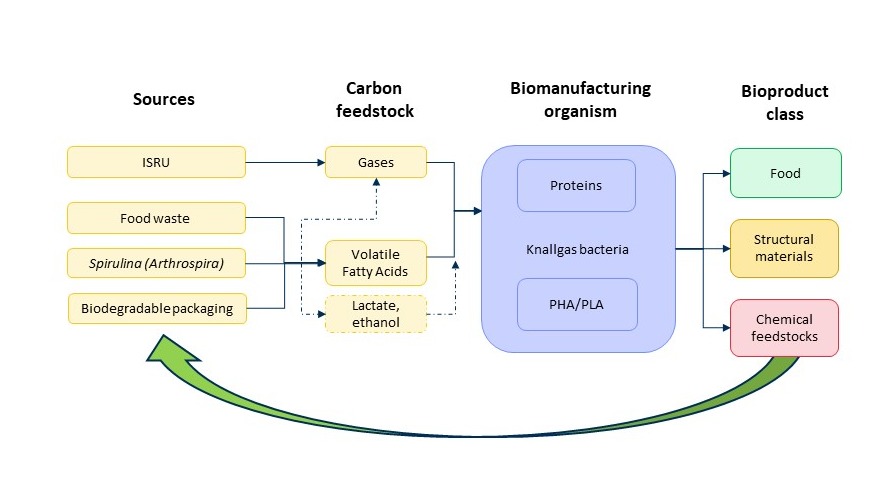

For long-term space missions, life support systems will have to replenish scarce resources and supply mission-critical items on demand. Materials were identified as prime targets for in-space biomanufacturing because of the large impact on payload capacity. Ideally the processes apply microbial species which have the flexibility to transform waste streams and CO2 or other in-situ resources into a range of valuable products. Cupriavidus necator has the desired substrate versatility and the capability of producing biopolymers. In a space context, a variety of waste transformation products will be available, including mixtures of volatile fatty acids, lactate, ethanol, and CO2. These are all suitable substrates for Cupriavidus growth and biopolymer production. Interestingly, Cupriavidus necator, the most studied organism for Polyhydroxyalkanoates (PHA) production, has recently been shown to also accumulate poly(3-hydroxybutyrate)/poly(lactic acid) (PHB/PLA), a feature which normally only occurs in genetically modified strains [1]. PHA and PLA are both biodegradable and biocompatible polymers, suitable for a range of medical, industrial, and agricultural applications. Blending both polymers expands their application potential to (food) packaging, cutlery, single-serve coffee pods, controlled release of active compounds, 3D printing, etc., while retaining biodegradability in the final products [2]. The novelty of this proposal is to demonstrate if and under which conditions combined PHA/PLA production is possible, and how the blend composition can be tuned using a variety of organic and gaseous substrates. If successful, this would represent a highly substrate- and product-flexible concept for on demand biomanufacturing of supplies and components.