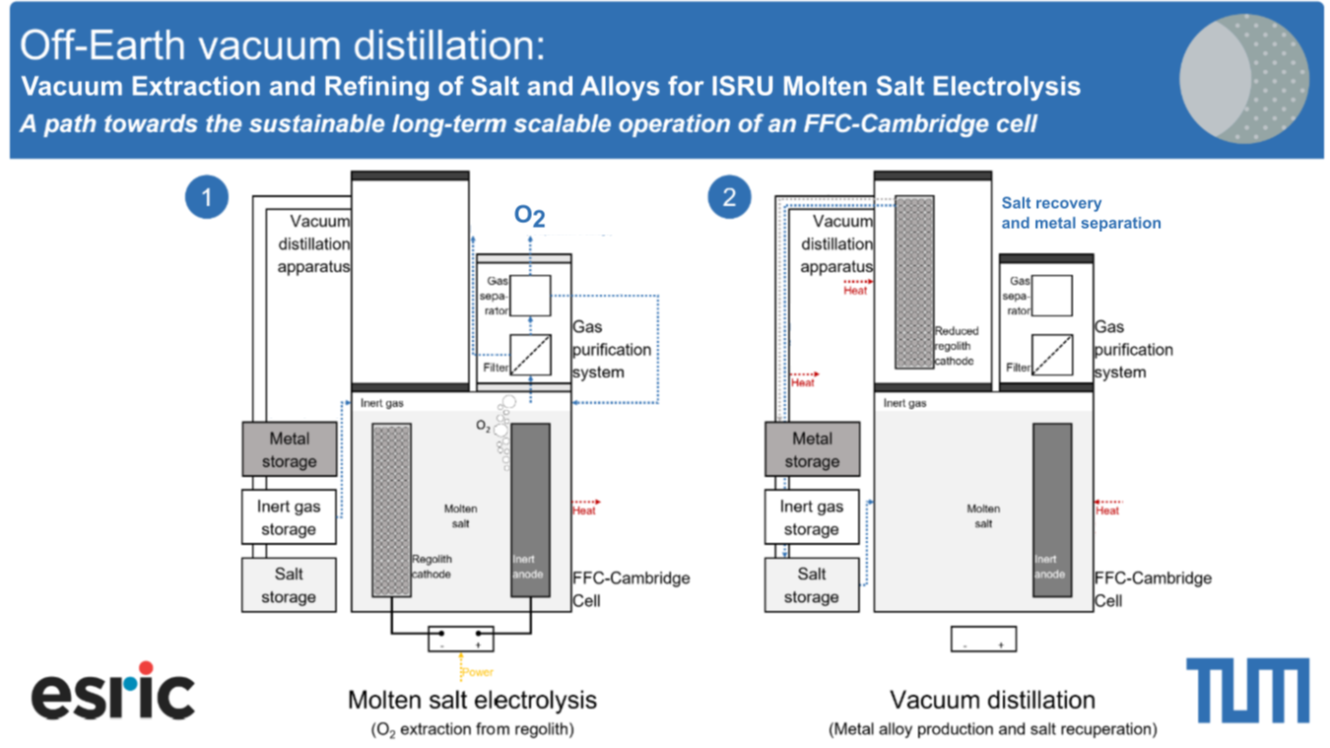

In-situ processes increase the flexibility and adaptability required for sustainable, long-term human space exploration. The molten salt electrolysis (MSE), in particular the FFC process, is a method for the electrochemical reduction of solid regolith in molten salts and currently the focus of ESA as the primary method for oxygen production on the Moon. Oxygen is the primary product, while metals play a critical role as byproducts to make the process economically viable. A key challenge is the separation and reuse of the salt from the solid reaction products, which is of great importance to make the process sustainable in the long term. Water intensive refining methods as in terrestrial applications are out of question due to the limited water availability on the lunar surface. Therefore, refining techniques that use the prevailing planetary environmental conditions to their advantage are of significant importance. Vacuum distillation (VD) separates compounds based on differences in their vapor pressures and could be included as a subsequent refining step after electrochemically reducing regolith. Prevailing vacuum or low ambient pressures, as found on the surface of the Moon or Mars lead to a reduction of the vapor point of compounds and thus the total energy requirement for the refining process. Moreover, VD has already been studied for terrestrial applications to recycle salts from MSE products, avoiding traditional water-intensive methods. For space exploration, recovering imbibed salt losses would reduce the number of required resupply missions from Earth. Currently, this still poses a major weakness of the MSE, and addressing this challenge will be essential in developing a competitive alternative to other presently available ISRU oxygen and metal extraction processes. To close this gap, VERSA aims to demonstrate the feasibility of VD for the separation of salt and metal in MSE processes.