The EU steel industry currently accounts for 5.7% of total EU GHG emissions [1]. As such, the European Commission identified the reduction of CO2 derived from steel production as crucial for meeting Paris Agreement on climate change [2]. At the present state of the art, Eurofer does not project green steel to be an economically viable alternative, as it estimates that it would cost 110-320€/t more to produce green steel from iron ore w.r.t. the traditional route [2].

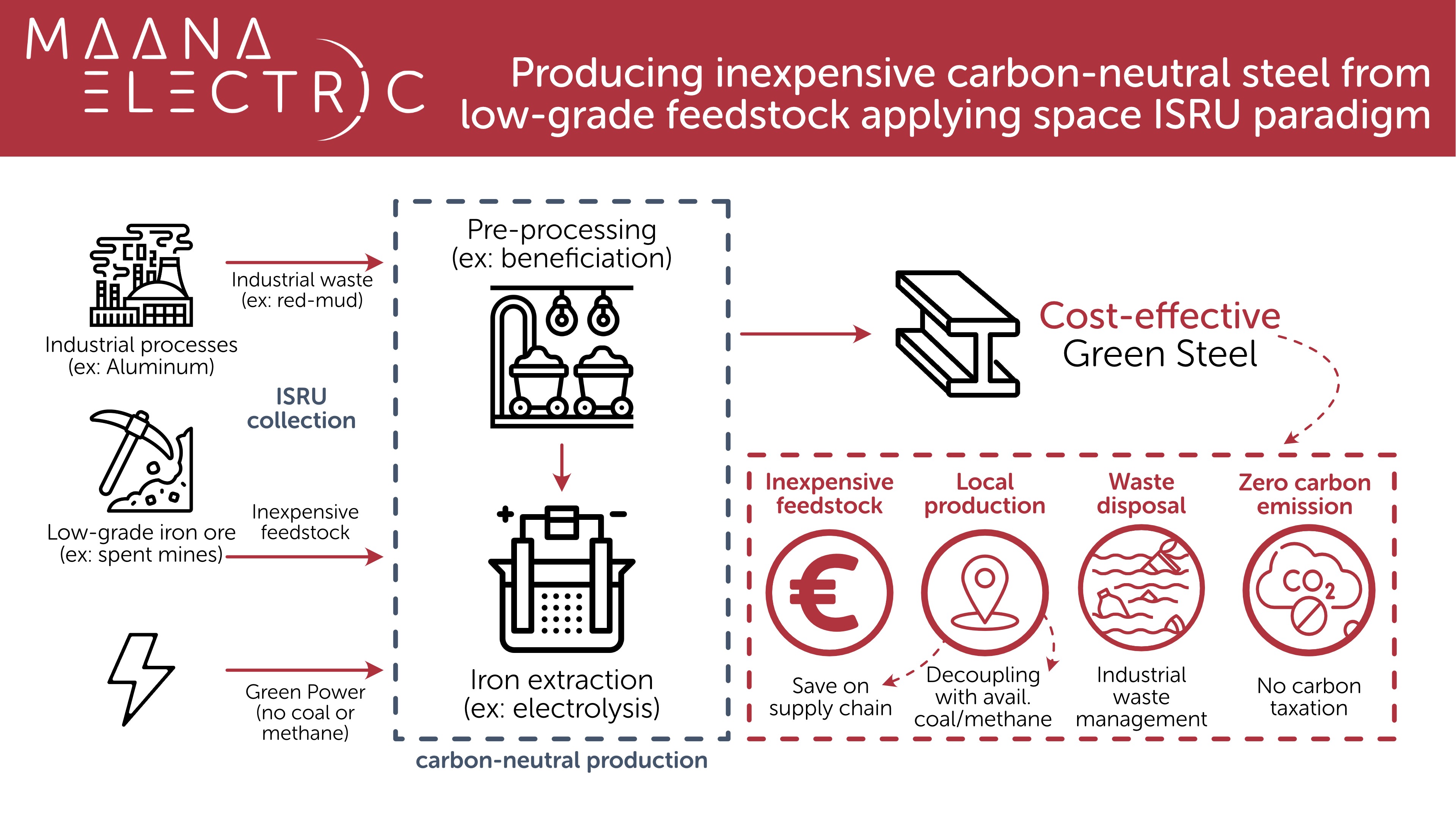

Any economically viable process must thus compensate this intrinsic increase in cost by a unique and production paradigm synergically compatible with green processes. The In-Situ Resources Utilization (ISRU) paradigm envisioned for future space exploration missions can aid in creating viable alternatives to traditional steel making processes, producing items from low-grade feedstock extracted in the proximity of the production site. In the first place, ISRU reduces the cost of the supply chain, in particular from transport and elimination of middlemen.

More importantly, ISRU technologies are compatible with low-grade feedstock allowing more green resource extraction (i.e less environmentally damaging mine sites) while addressing the rapid depletion of worldwide high-grade iron ore [3].

This approach would also allow to boost the circular economy, utilising waste from other industrial processes (i.e. red mud or sand processing waste).

Maana Electric, expert in ISRU processes for Si production, proposes to investigate the development of a European prototype system able to use only low-iron-grade feedstock and electricity as input to produce carbon-neutral iron with a competitive price against steel produced by carbon reduction of high-grade ore. Based on these observations, the approach proposed would have a short-term benefit for many European countries (such as Luxembourg) with large iron deposit but reduced availability of coal/methane [4], while pushing Europe as leader in green technologies.

[1] VUB. Industrial Value Chain: A Bridge towards a Carbon Neutral Europe. 2018.

[2] European Commission. Commission staff working document - Towards competitive and clean European steel. SWD(2021) 353. Brussels, 5.5.2021.

[3] Myers, N. Plan B 2.0: Rescuing a Planet Under Stress and a Civilization in Trouble. 2006.

[4] Thomas Koch Blank. "Green steel is a multi-billion dollar opportunity". 14/10/2020. Article the 8/11/2021 at https://www.greenbiz.com/article/green-steel-multi-billion-dollar-oppor….

[5] M. Draxler, A. Sormann, T. Kempken, T. Hauck, J.C. Pierret, J. Borlee, A. Di Donato, M. De Santis, C. Wang, “GREEN STEEL FOR EUROPE - Technology Assessment and Roadmapping”. Green Steel for Europe Consortium, Mach 2021.

[6] T. Kempken, T. Hauck, M. De Santis, P. Queipo Rodriguez, M. Miranda, D. Gonzalez, F. Simonelli, H. Vu, W. Szulc, D. Croon, J.T. Ghenda, Chuan Wang. “GREEN STEEL FOR EUROPE - Collection of possible decarbonisation barriers”. Green Steel for Europe Consortium, June 2021.

[7] T. Kempken, T. Hauck, Chuan Wang, M. De Santis, W. Szulc, M. Draxler, A. Sormann, P. Queipo, M. Miranda, D. Croon, J.T. Ghenda, J. Borlee, J.-C. Pierret, K. Peters. “GREEN STEEL FOR EUROPE - Decarbonisation Pathways 2030 and 2050”. Green Steel for Europe Consortium, June 2021.

[8] Mandova, H., Patrizio, P., Leduc, S., Kjärstad, J., Wang, C., Wetterlund, E., Kraxner, F. and Gale, W., (2019), “Achieving carbon-neutral iron and steelmaking in Europe through the deployment of bioenergy with carbon capture and storage,” Journal of Cleaner Production, Vol. 218, pp. 118-129.

[9] A. Lovagnini, L. Celiento, (2021), “TN1 - 1MW TerraBox prototype system detailed design”, CCN2 to ESA CONTRACT No. 4000125323/18/NL/MH/mg.

[10] P. Laznicka, (2010), “Giant Metallic Deposits - Future Sources of Industrial Metals”, Springer, Berlin, Heidelberg, doi: 10.1007/978-3-642-12405-1.

[11] Behera, P. R., Bhoi, B., Paramguru, R. K., Mukherjee, P. S., & Mishra, B. K. (2018). Hydrogen Plasma Smelting Reduction of Fe2O3. Metallurgical and Materials Transactions B, 50(1), 262–270. doi:10.1007/s11663-018-1464-8.

[12] Schleppi, J., Bromiley, G., Odling, N., & Bennett, N. S. (2021). In-situ resource utilisation manufacturing of optically transparent glass from lunar regolith simulant. Journal of Materials Science, 56(21), 12132–12153. doi:10.1007/s10853-021-06059-x