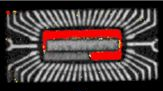

The various players in the space sector activities (equipment manufacturers, operators, and space agencies) are increasingly agreeing that the future belongs to industrial (or automotive-quality) components. Automotive-quality and commercial-quality components have already been selected and used for launcher-type or short duration missions applications. Metallographic cross section analyses made on plastic packages industrial components in the frame of these programmes revealed delaminations between the chip and the encapsulation resin. While these delaminations have generally been accepted for short-term missions, this is far from the case for long-term applications such as conventional satellites. As part of this subject (Idea), we would like : - To study how these delaminations evolve over time and the thermomechanical stresses imposed by the equipment/satellite qualification sequences, and the space environment, - To determine what are the most critical stresses for such type of plastic body components in the space environment, - - To settle a basis of criteria to be used to characterize these delaminations, and their level of acceptance