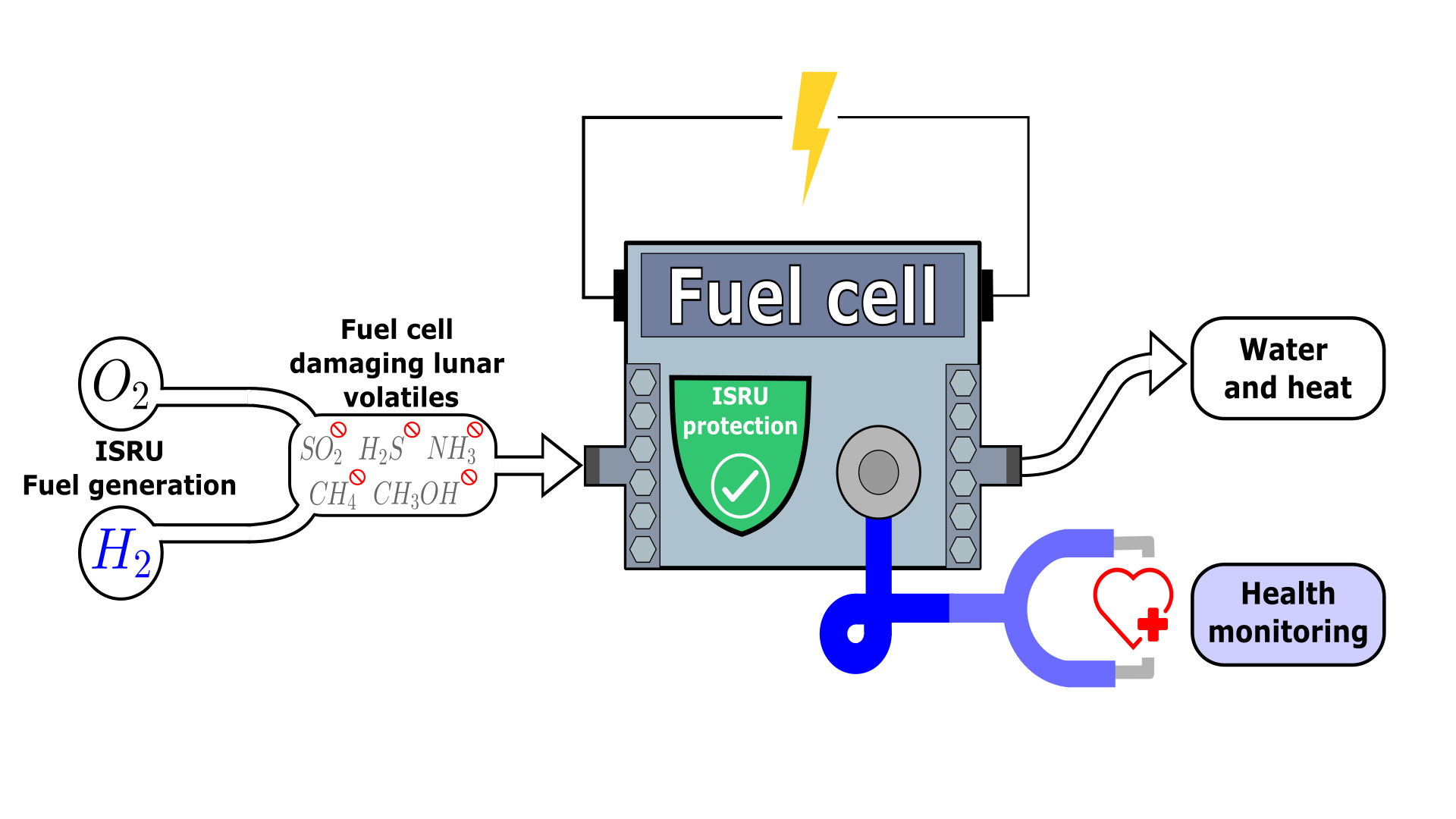

Fuel cell (FC) and electrolyser (EC) systems are a vital and space proven technology supporting the upcoming expansion of human presence into the solar system. In particular, unitized regenerative FCs pose an elegant energy storage solution. They are a robust power system benefiting from the high energy density of hydrogen while they can also be operated in reverse to electrolyse water (potentially derived from ISRU processes) creating fuel on demand. But while these properties are very promising, this technology needs to be adapted in order to endure harmful constituents in ISRU derived resources. For example, in the case of lunar ISRU, according to a publication from Colaprete et al. [6] large amounts of H2S, NH3, SO2 and CH3OH were spectroscopically detected alongside water in an ejecta plume originating from an impact into a permanently shadowed crater. All these chemicals are well-known catalyst poisons causing a premature system degradation and failure. Notably H2S and SO2 are problematic since conventional FCs require essentially sulphur free feed gases with a sulphur compound limit of only a few ppb. On earth these impurities are removed using complex energy intensive purification-methods before the fuel is in a usable condition, yet in the extreme environment of a lunar outpost less costly solutions will be essential. Thus, this work aims to study and improve the FC/EC resistance against ISRU derived catalyst poisons by introducing said impurities into the feed gas accompanied with accelerated stress tests. This will be accomplished by using bimetallic de-alloyed platinum-based catalysts, an adaptable catalyst which offers a wide range of compositional configurations. The output from this study would give the exploration community a fundamental insight into the behaviour of ISRU process output interactions with FC/EC stack technology - a critical understanding in successfully developing robust energy systems for Lunar but also Martian exploration.