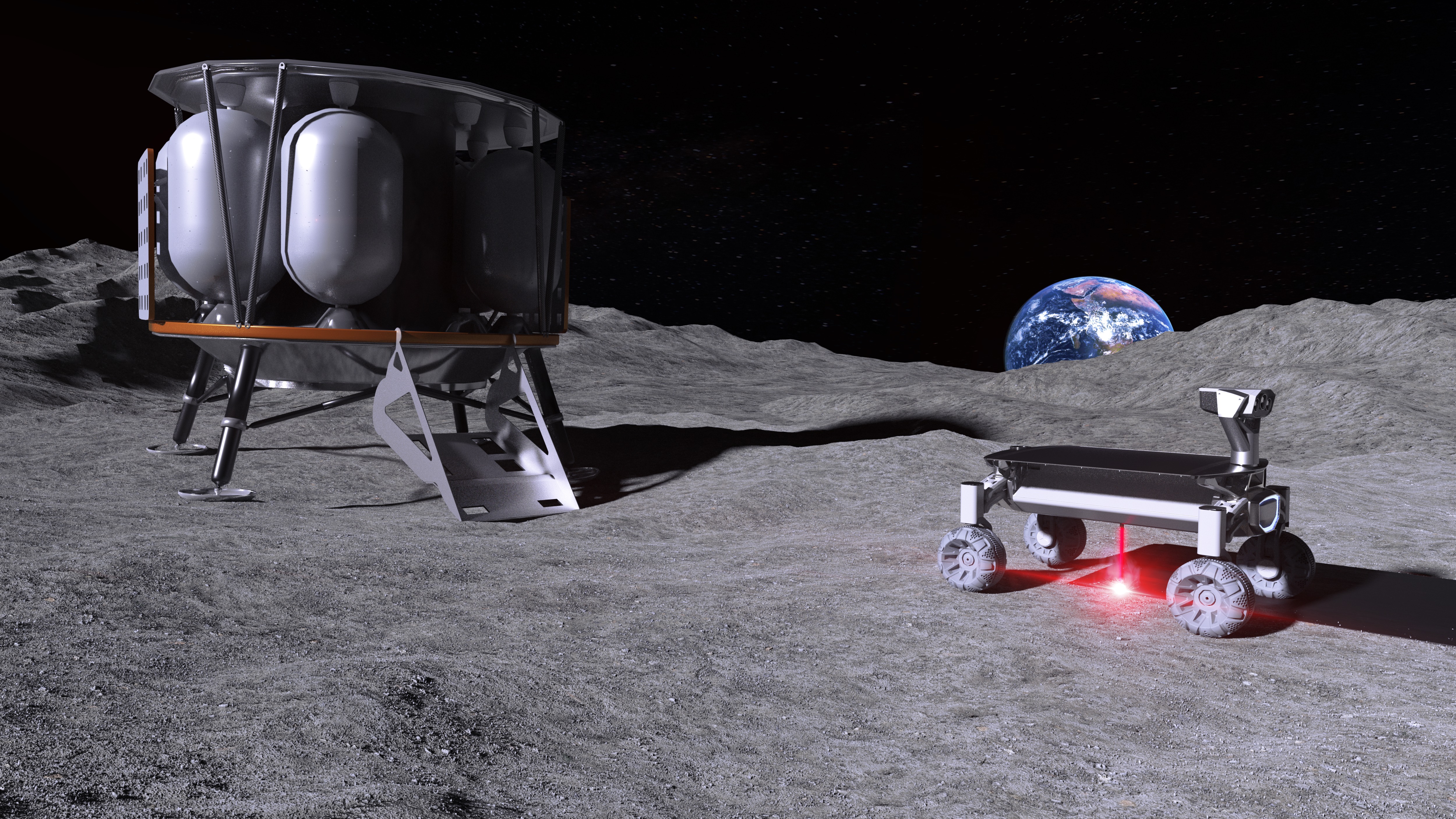

When setting up a lunar station, technologies for the use of locally available materials are crucial. Such technologies drastically reduce the need for transportation from Earth. Our idea aims to provide proof of a key technology, namely Mobile – Selective Laser Melting (M-SLM) for building large structures on the Moon. A mobile high power laser beam is directed on lunar regolith leading to its melting and after cooling to solid structures. Although various groups have been studying binder-free additive manufacturing techniques with potential lunar application such as laser-, solar power or microwave based methods, we think that using a laser is the best option, since it is independent from the sun and enables good precision as well as the potential for building large structures. M-SLM can be fully automated. Laser based processing tests of regolith simulants have been performed solely in laboratories on Earth, where it is impossible to fully simulate the lunar environment, resulting in unrealistic processes. Unknown, unpredictable effects can emerge on site and may have a big impact on processing results. For a proof-of-principle experiment for M-SLM on the lunar surface, we designed the MOONRISE payload, currently at post-PDR-status with an Engineering Model (EM) available. It consists of a high power laser capable of melting regolith at a fixed spot with parameters derived from laboratory experiments with regolith simulants under vacuum conditions. With this idea, we aim for an advanced application range compared to MOONRISE by exploring beam deflection concepts and their suitability for space. Our goal is to produce 2D-printed parts made of laser sintered lunar regolith simulant and evaluate their material properties with respect to deviation in shape, reproducibility and crystallite structures. This is an important milestone to enable 3D-printed parts on the lunar surface.