In recent years, there has been a resurgence in efforts for space exploration beyond Earth with plans for sending humans to the surface of the Moon and Mars. However, such long-term exploration missions are deemed expensive if they solely rely on the shipment of materials and equipment from Earth. To make such missions more affordable, in-situ resources could be used for on-site/on-orbit production of equipment and tools. Powder-based additive manufacturing (PBAM) is arguably one of the most promising process that enables the rapid production of weight-sensitive/multi-functional parts at small volumes and hence is a strong candidate for maturation for long-term future space missions to address the on-orbit manufacturing challenge.

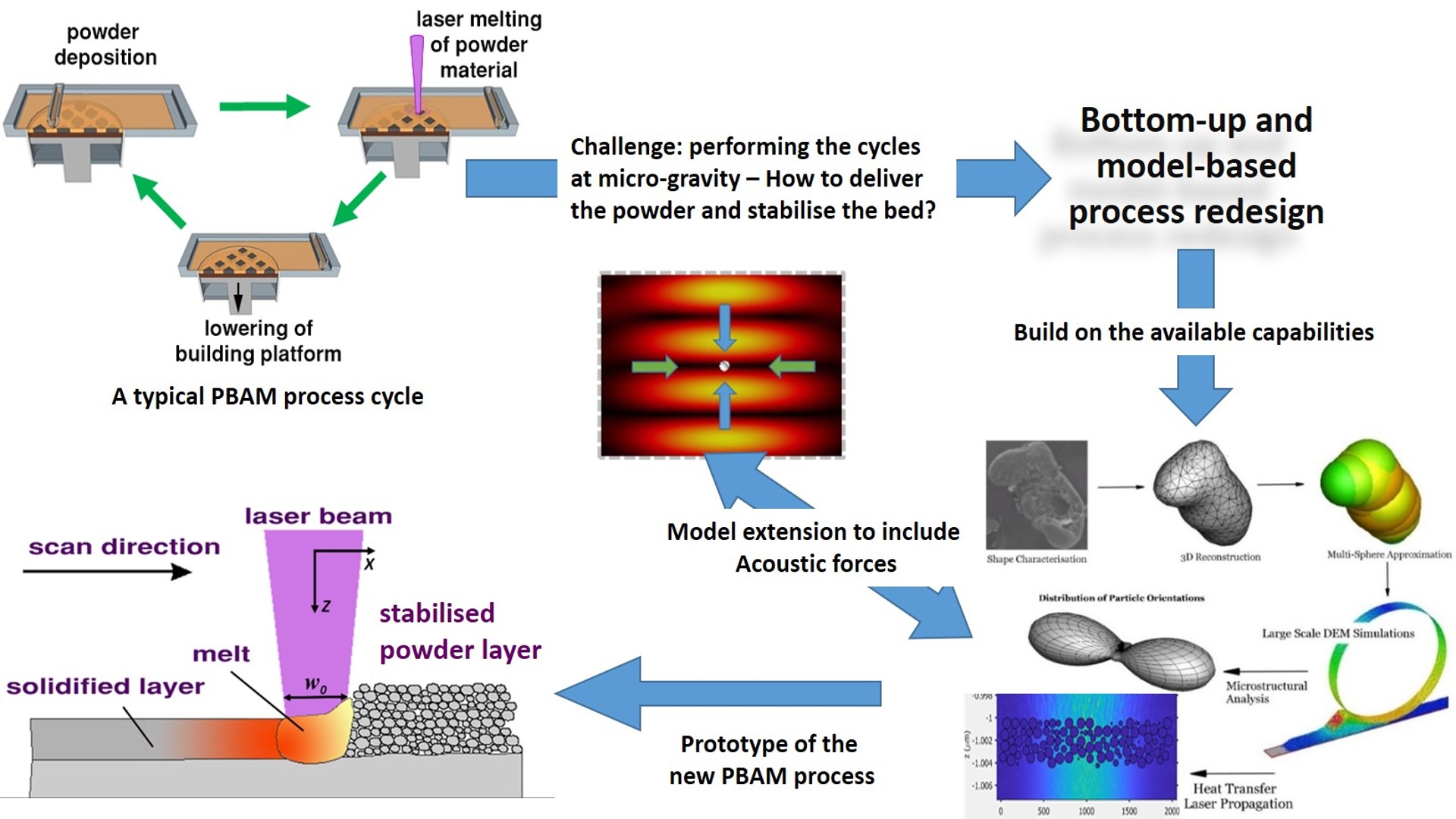

The process relies on three main stages:

- deposition of a layer of fine powder (Dp≈30 µm) to form a powder bed (~50 µm thick);

- laser heating;

- fusion of the grains through melting and solidification.

The aim of this research project is to deliver a totally new PBAM concept for a microgravity 3D printer for the production of small tools and components (O(50 cm)). This will be achieved via two Ph.Ds developing beyond state-of-the-art powder handling techniques including the use of dynamics-field ultrasonic devices to deliver the powder and stabilise the bed at the microgravity conditions.

In 2019 the German Space Centre attempted to developing a microgravity 3D printer. However, this design uses air suction to replace gravity for stabilisation of the bed which poses various technical issues such as difficulty in maintaining the gas flow after several layers of powder are applied. The proposed acoustic locking by utilising dynamic-field ultrasonic devices will offer many advantages including online digital process control (via micro-controllers), it is non-intrusive to the process and could be applied to multiple layers of powder.