- Larger sample size needed for larger coolers

Thermal analysis shows significant improvement on thermal efficiency and performance, demonstrated by boil-off measurements on samples

Process optimizations, analysis and qualifications necessary

- Structural analysis and verification on final joint geometry and material to be done on final application

- Pressure testing show encouraging results

Kovar for warm end material is not considered a show stopper, but

solution can also be found in alternate joint geometry

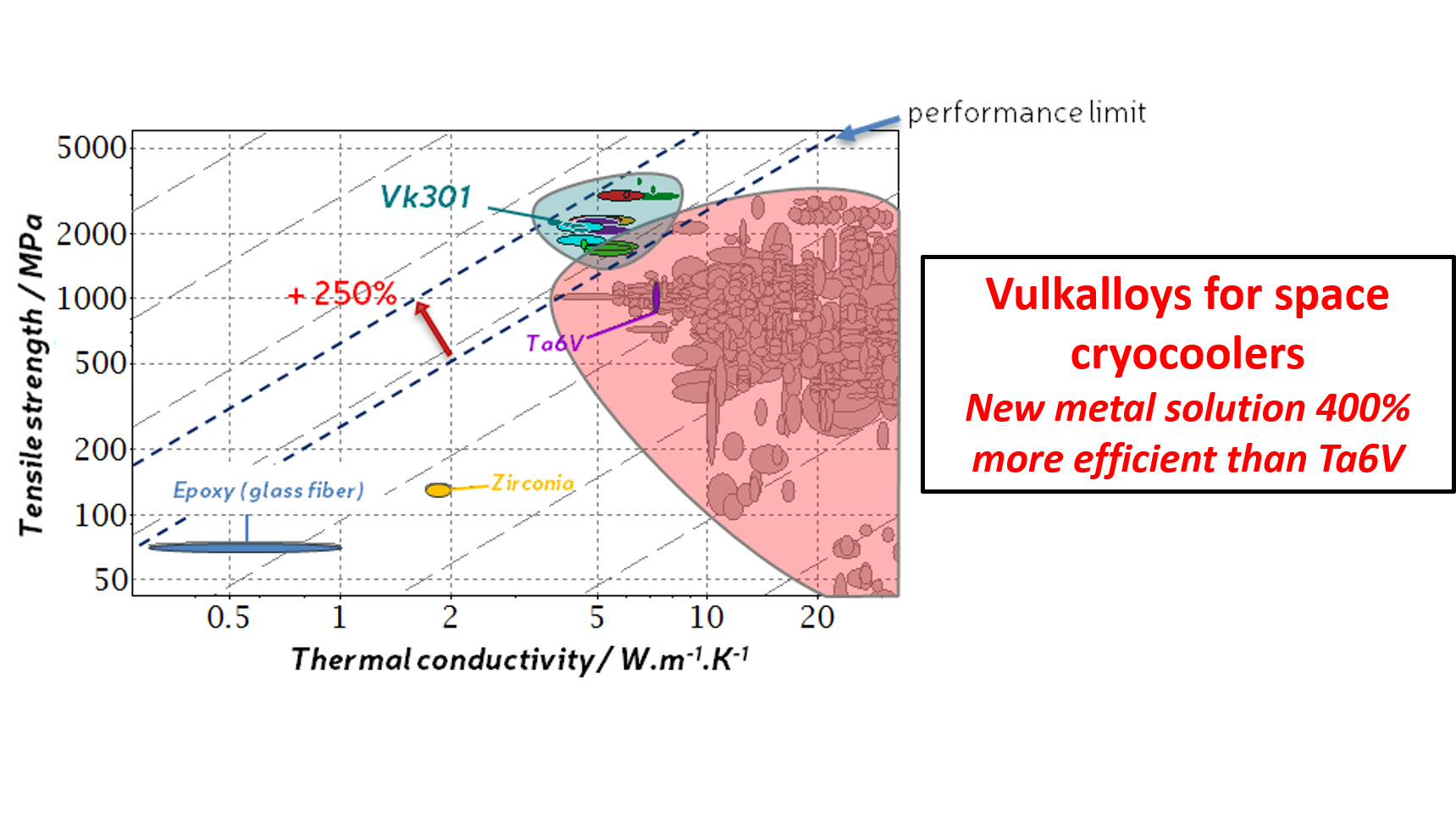

VULKAM, a French high-tech start-up specialized in amorphous metallic alloys (AMA), has developed a new range of materials with mechanical and thermal properties superior to those of Ti6Al4V. Vulkam is focusing on the industrialization and optimization of amorphous metals. Improving the efficiency of a cryogenic cooler is considered of great interest to space applications. Heat conduction losses in the cold finger of cryogenic coolers are one of the main causes of their lack of efficiency. The use of AMAs developed by Vulkam in collaboration with Lynred would reduce thermal conduction losses in these cold fingers by a factor of 2 to 4 and thus increase the efficiency of cryogenic coolers by several tens of percent. It therefore leads to significant improvements in the efficiency, and thus the required input power and reliability of the cryocooler, especially if they operate with lower cold tip temperatures. In this study, Vulkam, Lynred and Thales Cryogenics engage in a one-year evaluation to assess the potential of these new materials in compact space cryocoolers, with those main milestones:

- Check the requirements in terms of material quality assurance and control for space coolers,

- Study and select assembling methods of AMA to materials typically used in space coolers,

- Redesign an existing Pulse Tube cold finger using AMA,

- Make a theoretical estimation of the impact of the use of AMA on the dimensional design and MAIT of Pulse Tube cold fingers,

- Make an estimation of the impact of the use of AMA materials on the overall cooler performance, either in stand-alone or in redundant operational mode,

- Manufacture sample parts of reduced dimensions in order to obtain validation of the assembly methods between AMA and other materials, either by metal joints or by brazing or welding,

- Test and verify the robustness and helium tightness