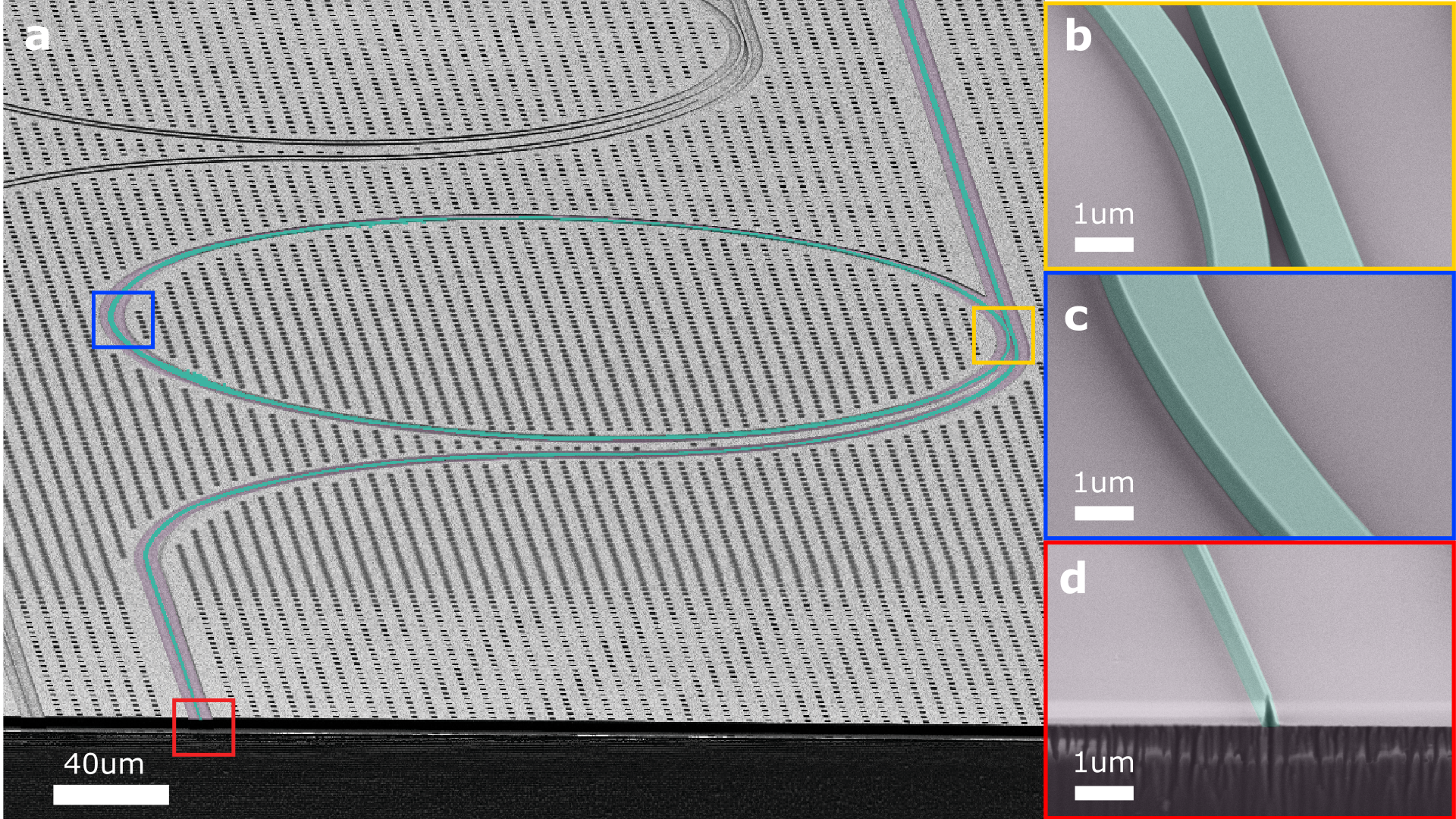

Recent advances at EPFL overcame this challenge, using a novel manufacturing process using Diamond-like carbon (DLC). DLC was discovered in the 1950s and is an amorphous material with excellent hardness and the ability to be deposited in nanometric thin films. Using DLC as a hard mask, EPFL demonstrated reliable manufacture of deeply etched, tightly confining, and low loss PICs with losses as low as 5 dB/m. This manufacturing approach can herald a new generation of tightly confining Lithium Niobate photonic integrated circuits, particularly for applications in coherent laser-based ranging, beamforming, optical communications, or emerging classical and quantum computing networks.

This project transitioned this manufacturing process to LUXTELLIGENCE SA, and to develop a process design kit (PDK) with key building blocks, specifically highspeed low voltage modulators aiming to become the first commercial pure-play foundry for LNOI in Europe and democratise access to Lithium Niobate integrated photonic circuits. The project focused on key technologies such as waveguide etching and electrode processing with demonstration of basic components such as waveguides and electro-optic phase shifters in a PDK library.

Photonic integrated circuits (PICs) are indispensable for data transmission within modern data centers and pervade multiple application spheres traditionally limited to bulk optics, such as LiDAR and biosensing. Recent advances in thin film Lithium Niobate (LNOI) have shown the major potential of Lithium niobate integrated photonic circuits, which exhibit strong Pockels effect enabling ultrafast and efficient electro-optical modulation but are difficult to process via dry etching. For this reason, etching tight confining waveguides - routinely achieved in silicon or silicon nitride - has not been possible, which has hampered the transition of the material to commercial foundries. Indeed, while silicon or indium phosphide are well developed, with many commercial foundries in Europe offering PDK (process design kits), this is not the case for Lithium Niobate PICs. Recent advances at EPFL have overcome this challenge, using a novel manufacturing process using Diamond-like carbon (DLC). DLC was discovered in the 1950s and is an amorphous material with excellent hardness and the ability to be deposited in nanometric thin films. Using DLC as a hard mask, EPFL demonstrated reliable manufacture of deeply etched, tightly confining, and low loss PICs with losses as low as 5.6 dB/m. This manufacturing approach can herald a new generation of tightly-confining Lithium Niobate photonic integrated circuits, particularly for applications in coherent laser-based ranging, beamforming, optical communications, or emerging classical and quantum computing networks. This project aims to transition this manufacturing process to a startup LUXTELLIGENCE SA, and to develop a PDK with key building blocks, specifically high-speed low voltage modulators. We aim to become the first commercial pure-play foundry for LNOI in Europe and democratize access to Lithium Niobate integrated photonic circuits.