Duration: 15 months

Different actuator technologies are based on key performance metrics such as size, response time, power consumption, durability, precision, price, mass manufacturing potential, and resistance to chemically challenging conditions. MEMS actuators stand out for their high precision and fast response time but come with high costs. Rvactuators’ MicroWire is a microscale solution with fast response time, low power consumption, and high mass manufacturing potential, making it a strong competitor. However, its durability remains uncertain and the capability needs to be proven during technology advancement stages and validations.

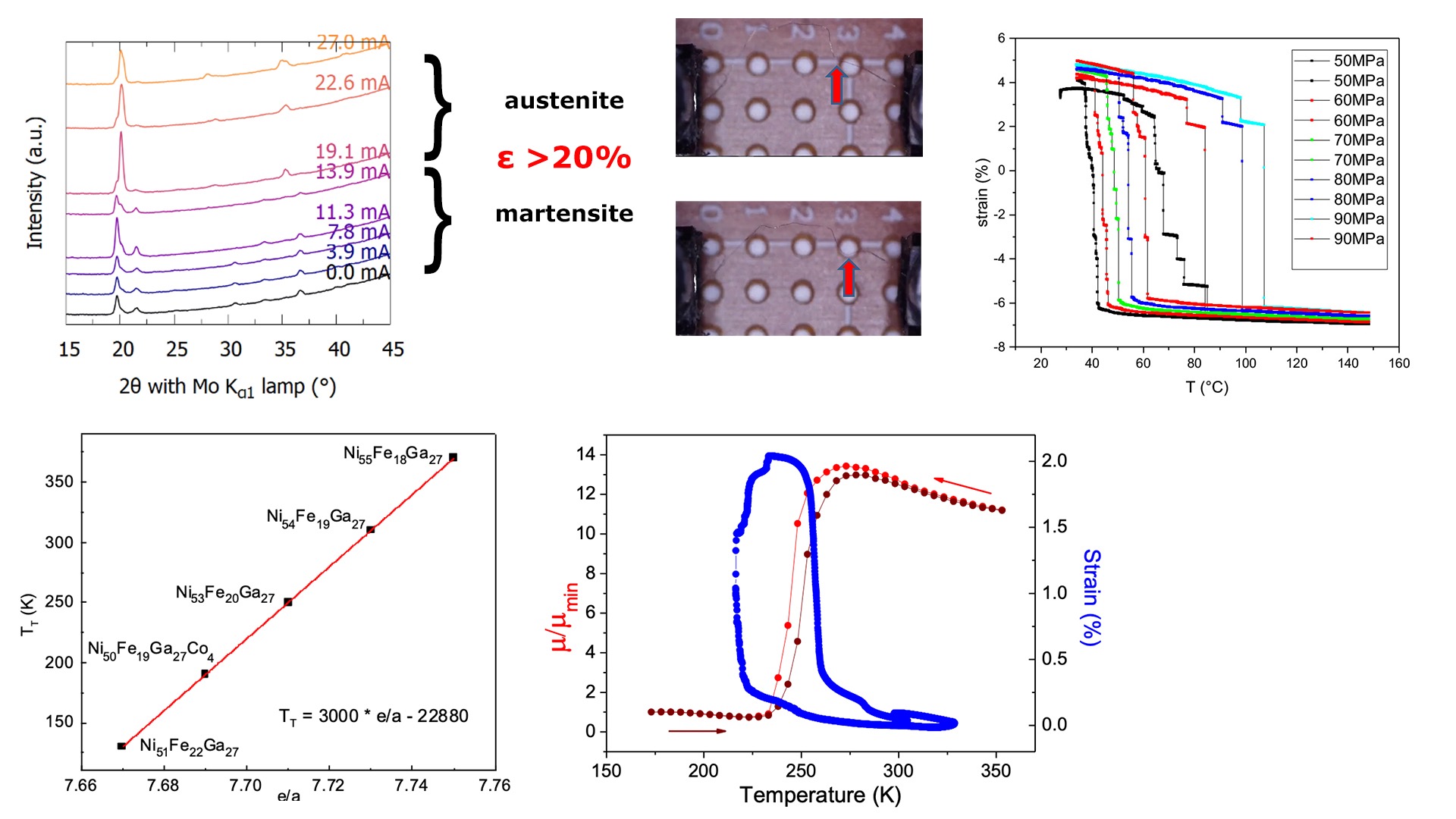

RVactuators’ MicroWire emerges as a promising alternative for applications requiring low power consumption, scalability, and resistance to chemically harsh environments. Wire shape introduces additional functionality into the shape memory materials. Wires show high straining in their axial direction. Moreover, shape anisotropy enhances the magnetic field induced straining. Taylor-Ulitovski method is used to produce NiFeGa glass-coated microwires, an inexpensive method that allows production of large volume of wires in short time. NiFeGa microwires show monocrystalline structure along entire wire length (up to 1 km) that is accompanied with shape memory reversible straining up to 12% without necessity of thermal treatment or training. It is possible to control the chemical composition very precisely, the transformation temperature can be easily tuned within 100 – 400 K.

Good mechanical properties allows repetitive structural transition over 1 000 000 times. Shape memory effect is connected to the easy magnetization axis change. As a result, structural transformation is accompanied with a huge variation of initial permeability (over 1000%) that can be used for precise phase detection. Such feature makes NiFeGa microwire ideal material for SMART actuators that can sense their actuation by themselves.