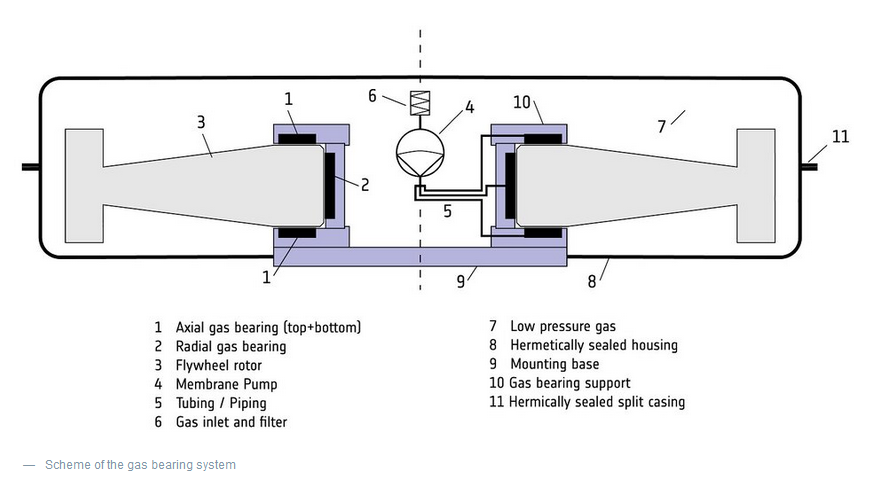

Precision and stability in satellite pointing are vital, especially in the small satellite industry. Gas Bearing Systems offer transformative potential, particularly in the successful collection of high-resolution Earth Observation and/or Science images and robust Inter-Satellite Laser Communications . Micro-vibrations may disrupt image quality and data accuracy. VEOWARE is committed to further develop and commercialise this invention as this solution is gaining high market traction as evidenced by the large number of Letters of Interest already received or promised from motivated customers. Gas bearing systems using ultrasonic pumps represent a novel non-contact approach, using a thin gas film to separate and support rotating components, eliminating physical contact. This eliminates friction and wear, enables exceptionally smooth rotations and drastically reduces micro-vibrations, ensuring high pointing stability.durability (launch). The primary objective of this project is to design a TRL4 demonstrator (BreadBoard Model, BBM) primarily employing off-the-shelf (COTS) components that is representative in form and function to the final product. The breadboard will comprise off-the-shelf piezoelectric pumps, while the bearings will be bespoke (suppliers already consulted), featuring well-designed nozzles for precise gas pressure regulation. The RW motor will be selected with proven heritage from Veoware. The BBM will undergo vibration testing to demonstrate robustness against launch loads. The BBM will be not only fully functional but also portable, allowing it to serve as a compelling BBM that can be showcased at various strategic events, including conferences and congresses. Within the scope of this technical maturation phase, our goal is to demonstrate exceptional micro-vibration reduction and confirm the bearing's durability (launch impact). The zero-crossing behavior will be analysed.