Lunar regolith can be sintered/melted by intensive solar or laser radiation to dense and rigid structures. 3D objects are obtained layer by layer. For reaching the required energy densities, sunlight can be focused by means of mirrors of lenses. A major concern is, however, the quality of parts manufactured. Moreover, building infrastructure requires a minimum productivity of processes engaged. Regolith is not simply compacted to arbitrary geometries when locally annealed by intensive light. A rapid densification of the generally fluffy powders is associated with melting and viscous flow resulting in a significant deformation of initially homogeneous powder beds. Light focused to small spots is favoured for obtaining parts with good geometrical definition, but productivity is generally low. Large spots would be needed for establishing infrastructural elements, such as roads, landing pads, but for the reasons mentioned structural integrity of parts manufactured will be low. We herewith propose a comprehensive study on the selective sintering of Lunar and Martian regolith in large areas at appropriate atmosphere, in combination with layer by layer sintering for the manufacture of 3D parts. Know-how acquired will lead to the construction of equipment capable to pave areas with molten regolith and to manufacture voluminous massive 3D structures.

A two-step approach is suggested:

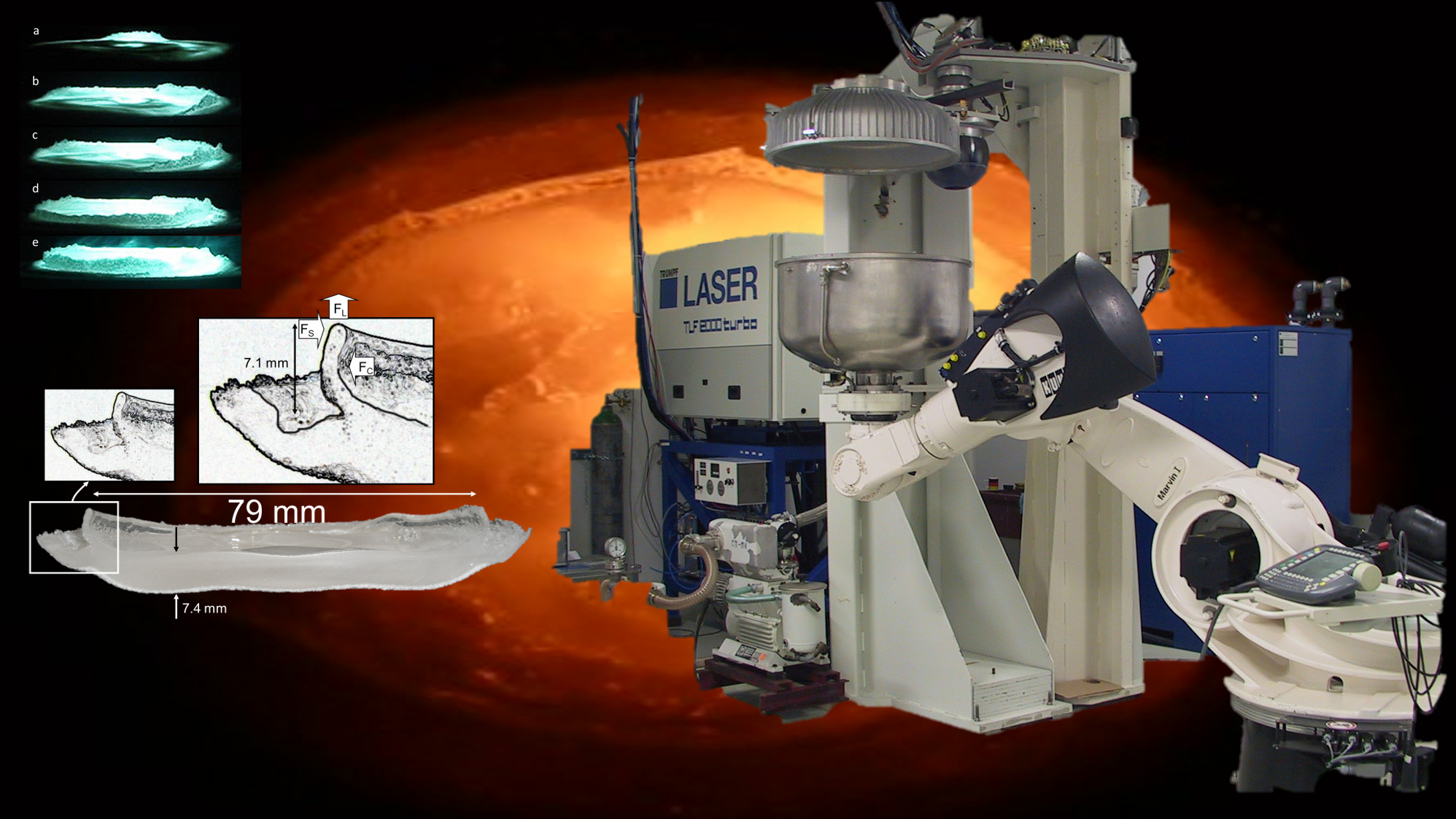

- Study of the sintering behavior of regolith in large spot local radiation. The equipment available comprises a 12 kW cw. CO2 Laser, telescope optics for variation of laser spot size up to 100 mm at parallel incident in a 1 m3 vacuum chamber.

- Know-how transfer to build an autonomously working sinter unit, using concentrated sunlight as energy source and the moon surface as powder bed.