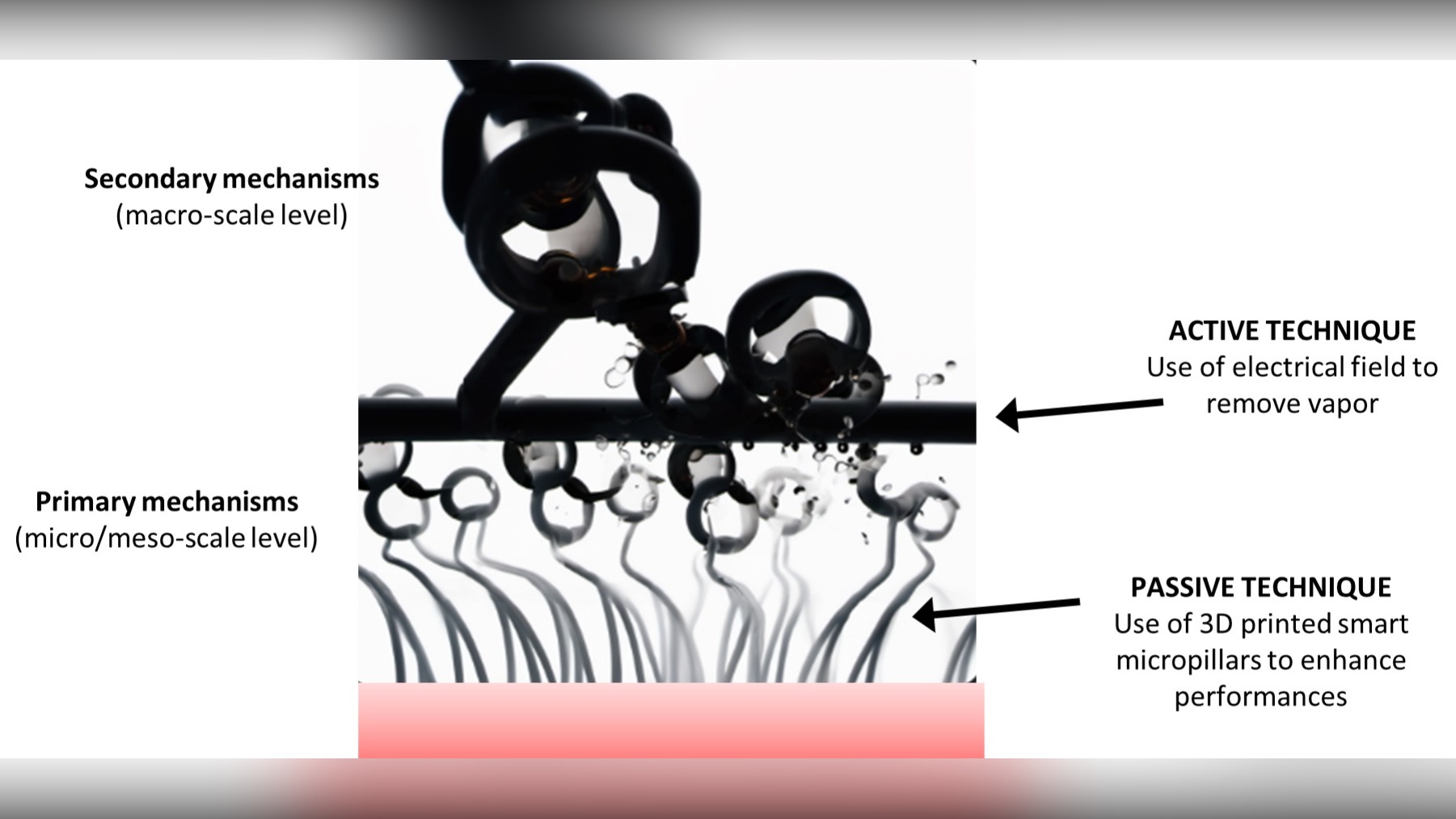

Efficient heat management is crucial for space applications, where traditional methods may fall short due to extreme conditions. Pool boiling, known for its high heat flux with minimal temperature differences, benefits from engineered structures that enhance boiling heat transfer due to multiple critical functions related to the expansion of surface area, the increase of nucleation site density, wettability, and capillary wicking. Shape memory materials (SMMs) offer a groundbreaking approach to thermal management due to their ability to adapt to temperature changes. However, the potential of SMMs in enhancing liquid-vapor phase change processes remains untapped. We aim to explore the utilization of SMMs to enhance pool boiling heat transfer in both normal and reduced gravity conditions. We will leverage additive manufacturing techniques to fabricate shape memory-engineered configurations, capitalizing on laser powder bed fusion technology to create smart surface structures. By manipulating surface properties and employing precise microstructure design, we aim to revolutionize thermal management. Our objectives are threefold:

1. Fabricate shape memory surface microstructures, mm to µm scales. We will employ laser powder bed fusion to demonstrate the smart structures.

2. Realize how the heat transfer and wetting phenomena are altered. Pool boiling experiments will be conducted with and without the application of electric fields, in terrestrial gravity.

3. Accelerated discovery of smart microstructures for reduced gravity. A proof of concept will be conducted to examine the effects of both a smart surface and an electric field under conditions of reduced gravity.

By achieving these objectives, we aim to develop radically new material sets and innovative approaches to thermal management. This research has the potential to significantly enhance heat transfer efficiency in space systems, thereby advancing the capabilities and reliability of future space missions.