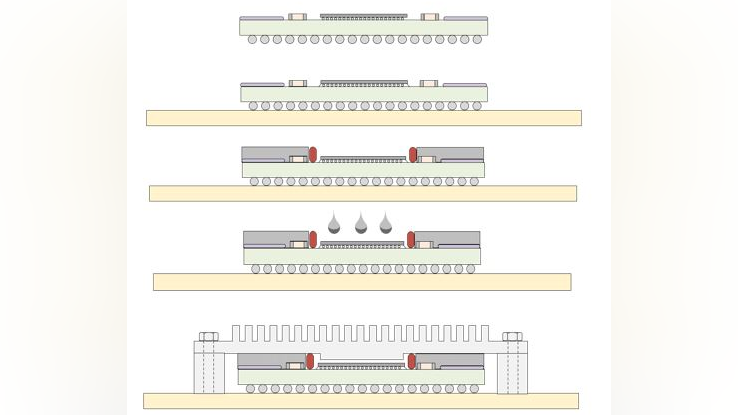

In the field of electronic integration, processors and FPGAs are becoming increasingly efficient, offering significant computational capabilities. This versatility enables a wide range of tasks to be completed quickly, but it also leads to a considerable amount of heat generation. The next generation of COTS processors, already available on the market, have eliminated the conventional thermal interface between the chip and the lid. Instead, they allow end-users to directly manage thermal management on the top of the chip. The conventional method of dissipating heat through traditional TIM (Thermal Interface Material) may reach limitations with such high dissipative components (>100W). Therefore, it is proposed to explore the use of liquid metal or equivalent materials as a TIM. This study aims to: Identify a technological solution. Define and implement a manufacturing process capable of containing liquid metal. Test the solution under various environmental conditions. By addressing these points, we can better understand the feasibility and effectiveness of using liquid metal as a TIM for high-performance electronic components and materials compatibilities.