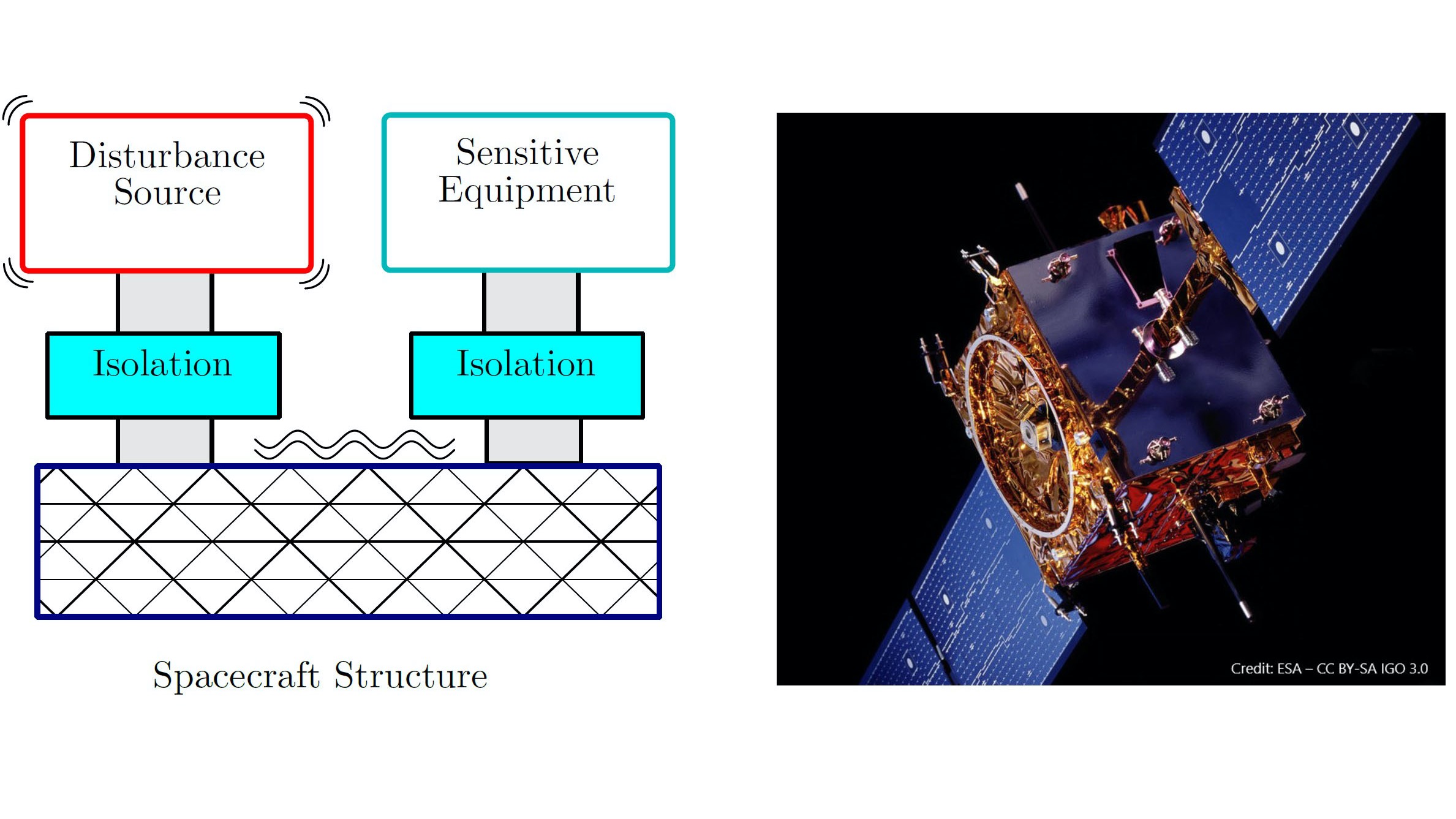

Future space missions will require extremely high pointing accuracy and an ultra-quiet environment for scientific instruments. This is a highly challenging problem since critical on-board equipment (e.g. reaction wheels, cryocoolers) generate significant levels of mechanical vibrations. With the advent of increasingly sensitive imaging sensors and more lightweight materials, understanding and controlling propagation of these disturbances is critically important. Passive isolators, such as elastomers, are currently used for vibration isolation, but they require tedious calibration for a particular load and mission constraints. Furthermore, low-frequent disturbances propagate through and can be even amplified by these isolators. Hence, a hybrid isolation strategy combining passive isolators and active control is aimed to be developed in this study.

The end goal is to realize a multi-purpose adaptive and fault-tolerant mechanical interface that provides broadband active vibration isolation for a variety of dynamic loads. The active platform would be driven by a digital control system capable of readjusting and accommodating changes in the dynamic response of the payload or the supporting spacecraft structure.

To achieve this objective, modular dynamic models, data-driven modeling tools-based on identification and machine learning, automatic optimal control synthesis and worst-case analysis algorithms using recent advances of the linear parameter-varying framework will be developed.

The resulting active mechanical interface could have a dramatic effect on future missions by allowing

- vibration isolation of noisy equipment (e.g. reaction wheels, solar array drive);

- vibration cancellation to take scientific measurements in an ultra-quiet environment;

- health monitoring of payloads as sudden changes in vibration signature, indicating equipment malfunction, could be identified and used to initiate autonomous actions to mitigate risks to the overall spacecraft.